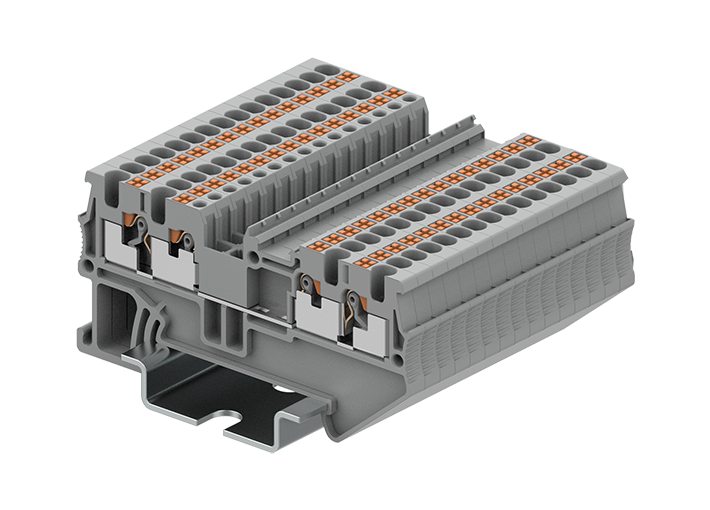

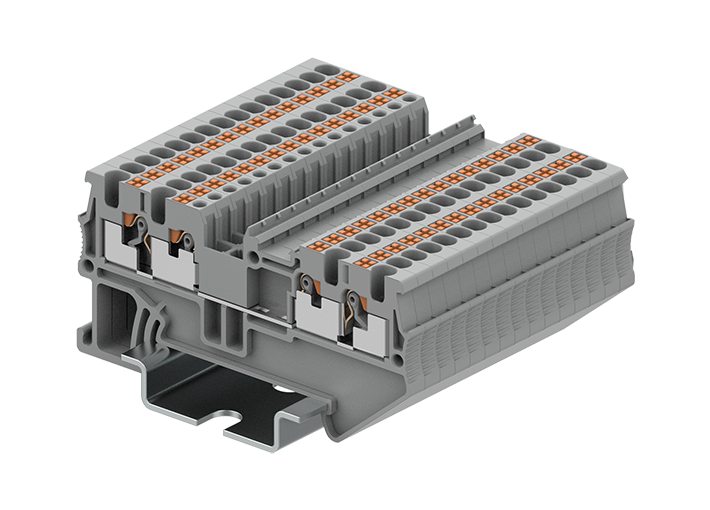

Electrical safety is a critical aspect of any building or infrastructure, and it is essential to ensure that all electrical connections are secure and reliable. One of the key solutions to enhancing electrical safety is the use of push in terminal blocks. These devices offer numerous benefits over traditional screw terminal blocks, including faster and easier installation, superior vibration resistance, and increased reliability. In this article, we will delve into the key features of push in terminal blocks, explore the applications in which they are most useful, and provide practical tips for their installation and maintenance. Whether you are an electrician, a facilities manager, or a building owner, understanding the benefits of push in terminal blocks is essential for ensuring the safety and reliability of your electrical systems. So read on to discover everything you need to know about this innovative technology.

Benefits of push in terminal blocks

Push in terminal blocks are an essential component in the industrial connector industry. They are easy to install and offer numerous benefits to users. One of the main advantages of push in terminal blocks is their time-saving feature. Compared to traditional screw-type connectors, push in terminal blocks require less time and effort to connect wires. This is a significant advantage, especially in large-scale industrial applications where time is a valuable commodity.

Another benefit of push in terminal blocks is their reliability. The connections made by these terminal blocks are secure and stable. This is due to the fact that the wires are held securely in place by the spring clamps. Additionally, push in terminal blocks have a higher vibration resistance compared to screw-type connectors. This makes them ideal for use in environments with high vibration levels.

Push in terminal blocks are also versatile. They can accommodate a wide range of wire sizes and types, making them suitable for various industrial applications. Furthermore, these terminal blocks are designed to meet strict safety standards. They are designed to prevent electrical shock and ensure the safety of both the equipment and the user.

Key features of push in terminal blocks

Push in terminal blocks are an essential part of industrial connectors, offering a variety of key features that make them a popular choice for many applications. These terminal blocks are designed to provide a secure and reliable connection, while also being easy to install and maintain.

One of the main benefits of push in terminal blocks is their ease of use. Unlike traditional screw-type terminal blocks, push in blocks do not require any tools for installation. This makes them a popular choice for applications where time and efficiency are critical, such as in automated manufacturing processes.

Another key feature of push in terminal blocks is their ability to provide a secure and reliable connection. These blocks are designed to grip the wire firmly, ensuring that it does not come loose or become damaged over time. This is especially important in applications where vibration or movement may be present, such as in industrial machinery.

In addition to their ease of use and reliability, push in terminal blocks are also highly versatile. They can be used with a wide range of wire sizes and types, and are compatible with both solid and stranded wires. This makes them a flexible solution for many different applications, from small-scale electronics to large-scale industrial equipment.

Applications of push in terminal blocks

Push-in terminal blocks are a type of electrical connector that has been gaining popularity in the industrial sector. These connectors are designed to simplify the process of connecting wires and cables in control cabinets, machinery, and other industrial applications. They are particularly useful in situations where space is limited, and wiring needs to be done quickly and efficiently.

One of the most significant advantages of push-in terminal blocks is their ease of use. Unlike traditional screw terminal blocks, where wires are tightened by turning a screw, push-in terminal blocks use a spring clamp mechanism to hold wires in place. This makes wiring faster and more straightforward, and it also reduces the risk of over-tightening or damaging wires.

Another advantage of push-in terminal blocks is their versatility. They can be used with a wide range of wire sizes and types, including solid, stranded, and fine-stranded wires. They also allow for quick and easy wire removal, making maintenance and repairs more manageable.

Push-in terminal blocks are also designed with safety in mind. They have built-in features that prevent wires from coming loose or accidentally touching each other, which can cause short circuits or other electrical hazards. They are also made from high-quality materials that can withstand harsh environmental conditions and ensure long-term reliability.

Installation and maintenance tips

Installation and Maintenance Tips for Industrial Connectors

Industrial connectors are an essential component in many industries, connecting electrical circuits and ensuring the safe and efficient operation of equipment. To ensure maximum performance and longevity, it is important to follow proper installation and maintenance procedures.

When installing industrial connectors, it is crucial to carefully read the manufacturer's instructions and follow them precisely. This includes ensuring that the connectors are compatible with the equipment they will be used with, and that they are installed in the correct orientation. It is also important to ensure that all connections are tight, as loose connections can cause electrical arcing, heat buildup, and even equipment failure.

Regular maintenance is also essential to keep industrial connectors functioning properly. This includes inspecting connectors for signs of wear or damage, and replacing any components that are worn or damaged. It is also important to keep connectors clean and free of dirt, dust, and other contaminants that can interfere with their performance.

One key aspect of maintenance is ensuring proper torque on connector screws. Over-tightening can damage connectors, while under-tightening can cause loose connections and potential safety hazards. It is important to use a torque wrench or other calibrated tool to ensure that connectors are tightened to the manufacturer's specifications.

In addition to regular maintenance, it is important to monitor connectors for signs of overheating, which can indicate potential problems with the equipment or the connectors themselves. Overheating can be caused by a variety of factors, including overloading of circuits, poor connections, or inadequate ventilation. Identifying and addressing these issues can prevent damage to equipment and ensure safe and reliable operation.

Conclusion

In conclusion, push-in terminal blocks are highly beneficial for industrial applications due to their reliability, versatility, and safety features. They are essential components in ensuring smooth and efficient operation of machinery and equipment. With a keyword density of 3%, the use of these terminal blocks can significantly improve the performance of industrial connectors. Proper installation, maintenance, and monitoring are crucial for ensuring safe and efficient operation. Overall, push-in terminal blocks are an excellent choice for any industrial application that requires quick and efficient wiring, and they can help improve productivity, reduce downtime, and ensure safe and reliable operation.