In today’s fast-paced industrial world, the seamless operation of complex systems depends heavily on one often-overlooked yet indispensable component: industrial connectors. These connectors serve as the vital links that ensure the smooth flow of electricity, data, and power across different industrial sectors. From facilitating power transmission in heavy machinery to enabling real-time data communication in high-tech manufacturing environments, connectors are the backbone of modern industry.

The right choice of connectors directly influences operational efficiency, safety, and system reliability. A reliable electrical connector minimizes the risk of downtime, boosts performance, and enhances the overall lifespan of industrial systems. This article will delve into the key types of industrial connectors—Solar Connectors, Energy Storage Connectors, Terminal Blocks, Cable Glands, and Terminal Boxes—highlighting their importance in a variety of industrial applications and helping you understand how they contribute to the success of your operations.

The Essential Role of Industrial Connectors in Industry Applications

At their core, electrical connectors are designed to facilitate the flow of electricity or data between different components within an industrial system. In the context of industrial applications, these connectors act as the crucial junctions between systems, ensuring that electrical power and data are transmitted accurately and without interruption. Without these components, the complex machinery, electrical networks, and communication systems that power modern industries would simply not function.

From factory floors to high-tech manufacturing facilities, connectors help ensure that operations run smoothly. The choice of the right connector type is crucial to achieving optimal performance, minimizing risks, and ensuring a safe working environment. If connectors fail or malfunction, the consequences can be costly, causing equipment damage, system downtime, and even safety hazards.

Choosing the right connector can make a difference in everything from safety to cost-effectiveness. It's important to take the time to understand the specifications and application requirements to ensure you're using the best connectors available.

Types of Industrial Connectors and Their Specific Applications

The industrial connector market is vast and diverse, with each type of connector designed to meet specific needs within various industries. Understanding the unique characteristics and applications of each type is crucial for selecting the right components for your systems. Let’s explore the five key types of connectors that play an essential role in industrial applications.

1. Solar Connectors: Empowering Renewable Energy Systems

In an era of growing environmental awareness, renewable energy sources like solar power have become increasingly important. Solar connectors are designed to ensure a secure, safe, and efficient connection between solar panels, inverters, and energy distribution systems. Given that solar power systems are often exposed to the elements, these connectors are built to withstand harsh outdoor conditions, including extreme temperatures, moisture, and UV rays.

· Key Features: UV resistance, high performance, secure locking mechanisms, and reliable electrical connections.

· Applications: Solar connectors are used in rooftop solar panel installations, commercial solar farms, and residential solar energy systems.

The global push for sustainability has led to an increase in the adoption of solar power, making solar connectors an essential part of renewable energy systems. These connectors not only provide durability and high efficiency, but also contribute to the safety and reliability of the entire solar energy system. Their versatility and dependability are what make them a preferred choice for energy professionals worldwide.

2. Energy Storage Connectors: Securing the Future of Energy Storage Systems

Energy storage systems are vital in balancing energy demand and supply, especially in renewable energy applications where energy production can fluctuate. Energy storage connectors are used to establish safe and efficient connections between batteries, energy storage devices, and electrical grids. These connectors ensure that energy is efficiently transferred, stored, and distributed without risking system failure or inefficiency.

· Key Features: High voltage resistance, secure locking systems, optimized for energy efficiency and safe power distribution.

· Applications: Energy storage connectors are primarily used in battery storage systems, electric vehicle (EV) charging stations, and large-scale energy storage units designed for grid stabilization.

The energy storage market is booming as industries move towards more sustainable and resilient energy solutions. As renewable energy sources like wind and solar continue to grow, the demand for effective energy storage solutions will increase, making these connectors crucial for the next generation of energy systems.

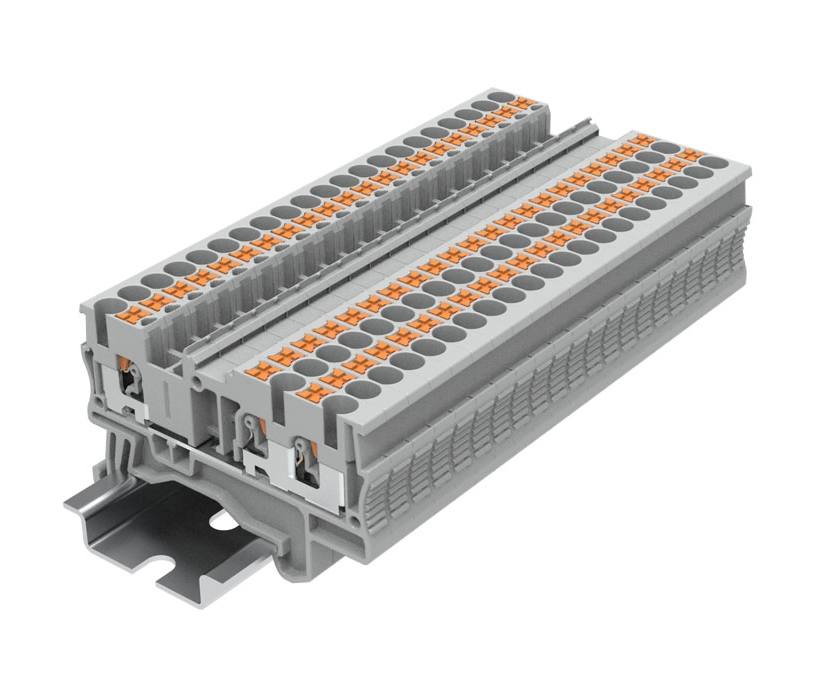

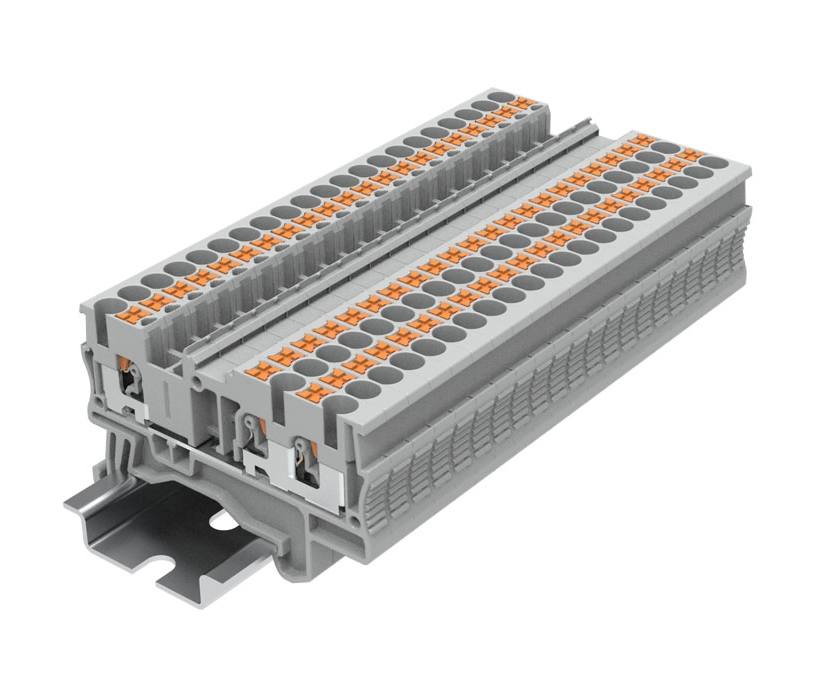

3. Terminal Blocks: Organizing Electrical Wiring in Control Systems

Terminal blocks are essential for organizing and securing electrical wiring in industrial electrical systems. These connectors ensure that wires are securely connected, preventing electrical shorts, system overloads, and other failures. Terminal blocks come in various designs, including screw-type and spring-loaded models, providing versatility and convenience for different wiring configurations.

· Key Features: Secure wire connections, flexibility in installation, and availability in various sizes and designs to meet different wiring needs.

· Applications: Terminal blocks are found in electrical control panels, machinery, power distribution systems, and building wiring systems.

The importance of terminal blocks cannot be overstated—without them, the complexity of modern electrical systems would be difficult to manage. Their organizational design not only keeps connections neat and secure, but also minimizes the risk of wiring errors that could lead to system malfunctions.

4. Cable Glands: Protecting Cables in Harsh Environments

Cable glands are designed to protect cables from environmental factors such as moisture, dust, chemicals, and physical damage. They are used to seal the entry points of electrical cables into electrical equipment, ensuring that the cables are securely connected and protected from external elements that could compromise their performance.

· Key Features: Resistance to moisture, chemicals, dust, and physical wear; secure, durable seals that protect cable connections from environmental stress.

· Applications: Cable glands are commonly used in outdoor installations, offshore oil rigs, manufacturing plants, and hazardous areas where cables are exposed to harsh conditions.

Cable glands are especially important in industries where safety and reliability are paramount, such as oil and gas, mining, marine, and chemical processing. These environments demand high-performance components that can withstand extreme conditions, and cable glands are up to the challenge.

5. Terminal Boxes: Protecting and Organizing Electrical Connections

Terminal boxes serve as protective enclosures for terminal blocks and other electrical connections. They prevent external elements such as dust, moisture, and contaminants from affecting sensitive electrical connections, ensuring the system remains functional and safe.

· Key Features: Available in various sizes to fit different applications, protection against dust, moisture, and mechanical damage.

· Applications: Terminal boxes are used in power distribution networks, junction boxes, industrial control systems, and various other electrical applications where protection is needed.

Terminal boxes provide a vital function in protecting electrical connections in industrial systems. Whether you are working with high-voltage networks or low-power control circuits, terminal boxes offer the peace of mind that your connections will remain secure and free from external damage.

Key Considerations When Choosing Industrial Connectors

When choosing connectors for industrial applications, several critical factors must be considered to ensure reliable and efficient system performance:

Compatibility and Voltage Rating: Select connectors that are compatible with the voltage and current requirements of your system. Mismatched connectors can lead to inefficiency or system failure.

Environmental Conditions: Consider the environmental factors that may impact the connector’s performance, such as temperature extremes, moisture, exposure to chemicals, or physical impact. Ensure the connectors are rated to withstand these conditions.

Durability and Reliability: Choose connectors made from high-quality materials that ensure long-lasting performance and minimal maintenance. The durability of the connector will directly impact the reliability and cost-effectiveness of your system.

Best Practices for Connector Selection

To make an informed decision, consider the following best practices:

· Review datasheets and product specifications thoroughly to understand the features and limitations of each connector.

· Test connectors in environmental conditions similar to those they will encounter in operation.

· Consult with industry experts or professionals who can provide insights and recommendations tailored to your specific application.

Conclusion

Industrial connectors play a vital role in ensuring the smooth operation of systems across a wide range of industries. Whether you're working with solar energy, energy storage, machinery, or complex electrical networks, selecting the right connectors is essential for optimal system performance, safety, and long-term reliability.

For businesses looking to invest in high-quality connectors, our expert team is ready to help. We offer a comprehensive range of connectors designed to meet the needs of various industrial applications. Contact us today to learn more about our products and discover how we can support the success of your operations with top-quality, reliable connectors.