Description

The Silicone Rubber Composite Pin Insulator is engineered for durability and performance in high-voltage electrical systems. Crafted from composite insulating materials, it offers exceptional creepage distance and mechanical strength. Its unique aerodynamic design ensures reliable operation in various environmental conditions. The self-cleaning properties and high-temperature resistance make it a preferred choice for demanding applications, reducing maintenance while maximizing safety.

Product Features

Material Composition:

Made from premium composite insulating materials and end fittings, ensuring effective electrical insulation and mechanical support.

Creepage Distance:

The extended insulating rubber shed design enhances creepage distance, resulting in excellent insulation performance in wet and polluted environments.

Mechanical Performance:

High mechanical strength is achieved through superior crimping with advanced rod materials and fittings, ensuring long-lasting reliability.

Connection Protection:

Fittings are safeguarded by a zinc layer, enhancing durability. Connections undergo ultrasonic testing and utilize a computer-controlled coaxial pressure crimping process for superior reliability.

Aerodynamic Design:

The silicone rubber shed's aerodynamic shape, combined with integral shaping technology, guarantees effective creepage distances across various climates and pollution levels.

Self-Cleaning Ability:

Enhanced self-cleaning capabilities in the air reduce maintenance requirements, ensuring ongoing performance without frequent servicing.

High-Temperature Resistance:

Constructed with ECR (Enhanced Corrosion Resistance) high-temperature reinforced materials, the insulator remains durable under extreme conditions.

Waterproof Design:

Features a labyrinth-type waterproof design between fittings and the rod, utilizing outsourcing glue technology to significantly improve waterproof and anti-seepage performance.

Application Scenarios:

Ideal for use in distribution systems, this insulator enhances overall system reliability and performance, making it an essential component in high-voltage electrical applications.

How to Use

To install the Silicone Rubber Composite Pin Insulator, ensure proper alignment with the pin structure. Secure the connections, ensuring they are tightly crimped and protected against polarity reversal. Regular inspections are recommended to maintain optimal performance and safety.

Technical Details:

| Type | Rated voltage(kV) | Specified bending load (kN) | Length *H (mm) | Dry arcing distance *L (mm) | Minimum creepage distance (mm) | Dry lightning impulse withstand voltage (kV) | Wet power frequency withstand voltage (kV) |

| FPQ-10/2 | 10 | 2 | 215 | 145 | 350 | 90 | 40 |

| FPQ-10/3 | 10 | 3 | 215 | 145 | 350 | 90 | 40 |

| FPQ-10/4 | 10 | 4 | 215 | 145 | 350 | 90 | 40 |

| FPQ-10/5 | 10 | 5 | 215 | 145 | 350 | 90 | 40 |

| FPQ-20/6 | 20 | 6 | 354 | 224 | 700 | 170 | 75 |

| FPQ-20/12 | 20 | 12 | 430 | 300 | 850 | 170 | 75 |

| FPQ-35/8 | 35 | 8 | 610 | 465 | 1400 | 170 | 75 |

| FPQ-35/10 | 35 | 10 | 462 | 320 | 900 | 170 | 75 |

Remark: *H, *L, please refer to related product drawings.

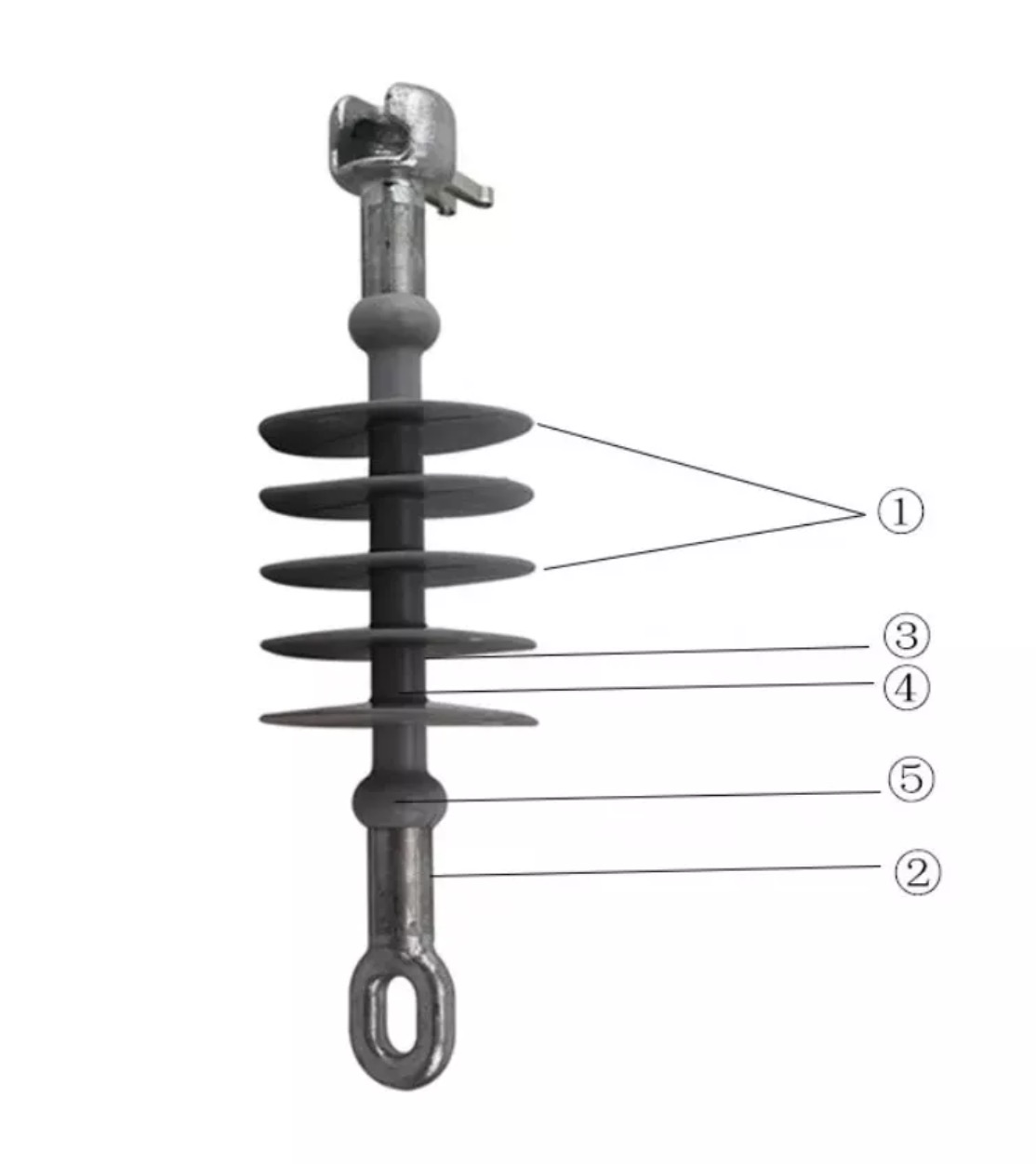

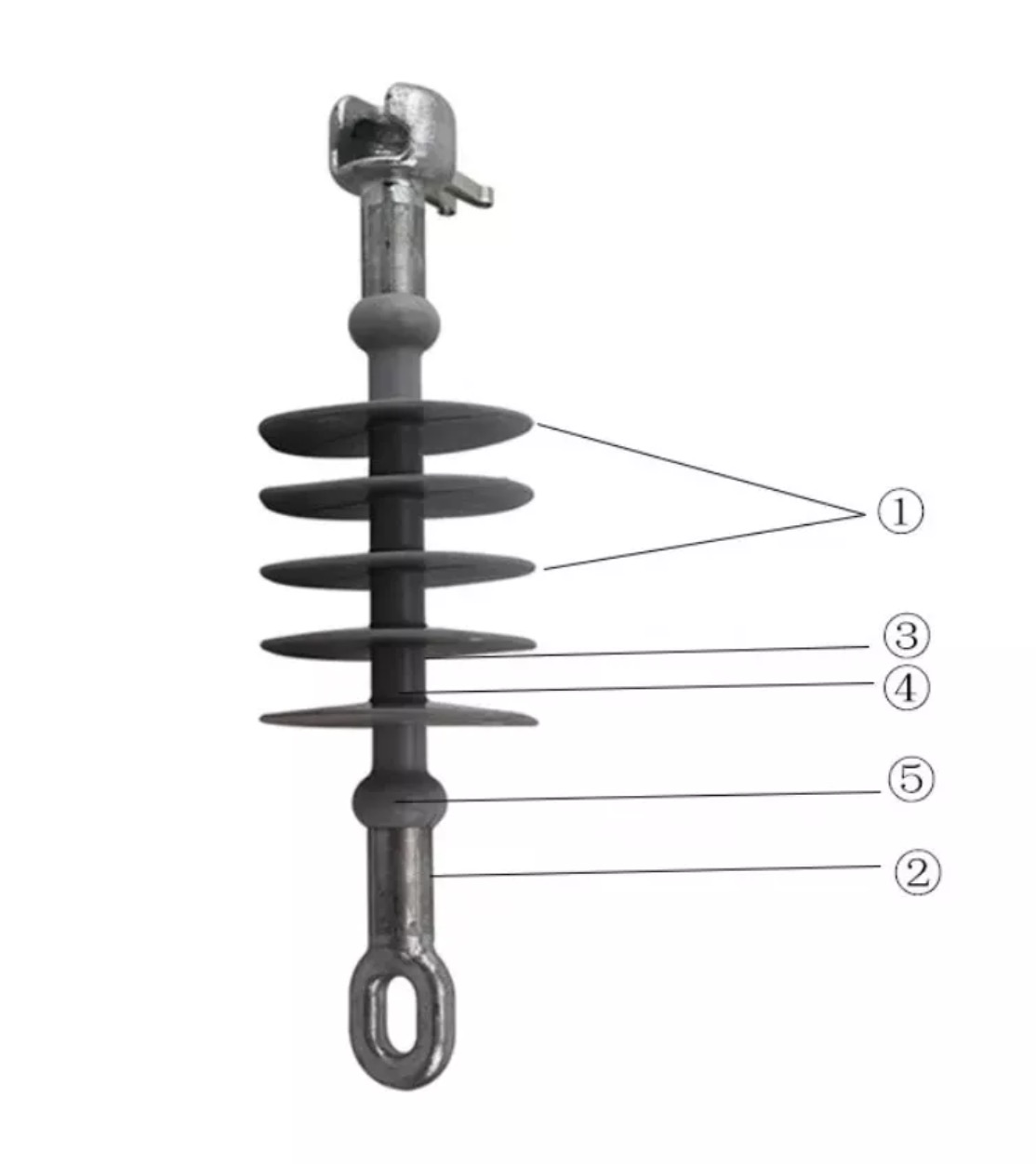

① Shed connected with core by integral forming

② Metal end fittings, core and sheds connected by new crimping process

③ The thickness of housing > 3mm, uniform thickness, confirm to IEC Standard

④ Acid resistant, high temperature resistant of epoxy fiberglass core

⑤ The material of metal end fittings is used with hot galvanization and technology of rare earth aluminum coating to avoid coating shedding when crimping, prolonging the service life of the product.

FAQs

What is the voltage rating of this insulator?

The Silicone Rubber Composite Pin Insulator is designed for applications up to 33kV.

Is this insulator suitable for harsh environments?

Yes, it is engineered for high-performance in polluted and extreme climatic conditions.

How does the self-cleaning feature work?

The insulator's design enhances its ability to shed contaminants, reducing the need for maintenance.