Comparison of spring clamping and screw clamping

The SMICO terminal has confirmed to many customers the actual use of the terminal. Taking manual wiring as an example, the spring-clamped terminal is more than 45% less used than the screw-type terminal. Even when compared with an electric screwdriver, the spring clamping still has the advantage of saving time. (In many applications, wire preparation, such as crimping wire ends, cold splices, or tinning, saves even more time.) The screw-clamping link is "completely operator-dependent", i.e. the screw-clamped The degree of tightness requires the operator's judgment. This may be more or less controlled with the operator's specific torque screwdriver's factory setting. When wiring in the field, it is more difficult to ensure the proper degree of screw clamping. The spring auto-clamping feature allows less skilled operators to complete joints with high quality. Accurate and consistent contact connections can be completed no matter who is operating. The tool used is just a standard screwdriver.

About SMICO Spring Terminal Blocks

1. SMICO spring terminal block has front wiring, side wiring and 45° wiring form

2. The wiring steps of the spring terminal: insert the tool - insert the wire with the stripped insulation layer - pull out the tool, the wire is automatically clamped.

3. The SMICO spring terminal can automatically adjust the clamping force according to the wire diameter of the wire, and the same quality can be achieved regardless of whether the operator is skilled or not.

4. The contacts of the SMICO spring terminal block can be airtight, the contact resistance is small, anti-corrosion, vibration resistance, stamping resistance, shorten the maintenance time and prolong the maintenance period.

Spring terminals do not require frequent inspection or retightening of terminals that have become loose due to disturbances, temperature cycling, or broken strands. The inherent reliability of spring terminals reduces downtime and user repairs. According to statistics, 35-50% of equipment maintenance is due to bad contacts. Considering the high cost of maintenance and lost production time, this savings is significant.

For the purpose of safety, reliability and ease of troubleshooting, many industry and national standards specify "one wire per tightening point".

SMICO spring terminal blocks can provide users with terminals for two-wire, three-wire, and four-wire contacts. The same jumper bridge applied to the upper insulation can easily connect adjacent or spaced terminals together. In both cases, each wire has its own contact clamp, and due to the front wiring feature, it does not require the larger space of a two-wire terminal.

The spring clamp has been designed to give proportional tightening force according to the wire size. The thicker the wire diameter, the greater the clamping force. The flat surface area of the spring in combination with the deflector bar with a special curved surface provides a secure connection that does not damage the wire. At the same time, the special design of the spring angle, when the pulling force is applied, also increases the clamping force.

SMICO spring terminal blocks and connectors have a complete wire entry, which can be tightly clamped to the wire. The shell design of the product, combined with the unique properties of the spring, can ensure that the wire is automatically positioned in the contact area, which can effectively prevent the stranded wire from unraveling.

Basic Information

SMICO ID | PTD4-2-PE |

| Pitch | 6.2mm |

| Number of levels | 1 |

| Number of connections | 4P |

| Connection method | Push in spring terminal |

| Protection Level | IP20 |

| Work temperature | -40~+105℃ |

IEC Data

| Rated Current | / |

| Rated Voltage | / |

| Overvoltage category | Ⅲ |

| Pollution degree | 3 |

| Rated impulse voltage | 6KV |

| Conductor cross section solid | 0.2-6mm² |

| Conductor cross section flexible | 0.2-4mm² |

| Conductor cross section flexible,with furrule | 0.2-4mm² |

| Stripping length | 8-10mm |

UL Data

| Use group | B | C | D |

| Rated Current | / | / | - |

| Rated Voltage | / | / | - |

| Rated cross section | 26-12AWG | - | - |

Material Date

| Insulation material | PA66 |

| Insulation material group | Ⅲa |

| Flame retardant grade, UL94 compliance | V0 |

| Contact material | Copper alloy |

| Surface characteristics | Sn,Plated |

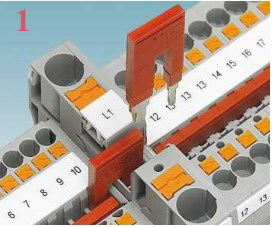

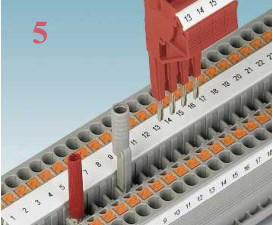

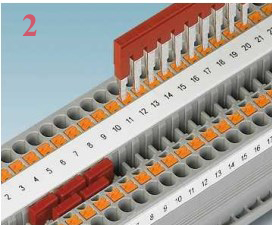

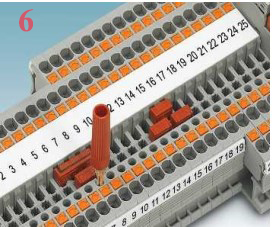

1.The reducing bridge allows terminal blocks with different nominal cross sections to be

connected with ease, e.g., a PT 10 push-in terminal block to a PT 2,5. Power blocks can be

created quickly using the re-ducing bridge.

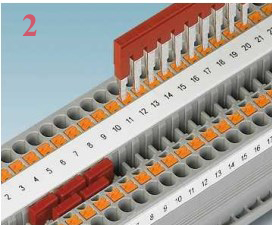

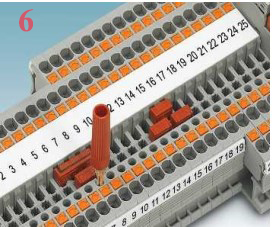

2.The double function shaft can be used to connect any number of terminal blocks with two-

position bridges. The 2 to 50-pos.bridges allow up to 50 terminal blocks to be bridged in

one step.

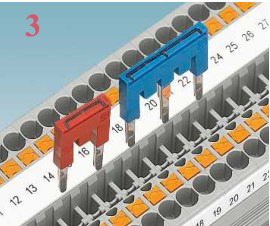

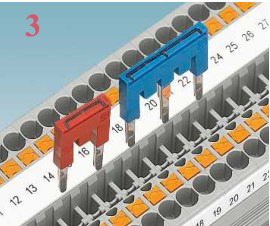

3.A jumping bridge is created by removing individual contact guides from the standard

bridge. Two potentials can then be routed in parallel. The contact points can also be

marked.

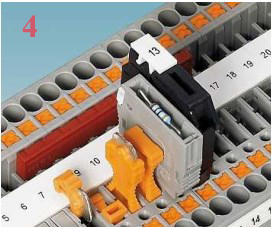

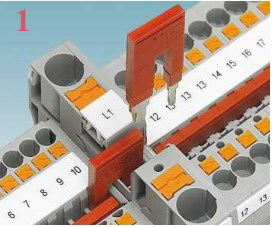

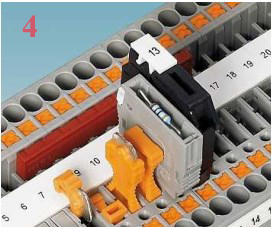

4.The P-FIX isolated feed-through connec-tor, P-DI isolating plug, P-CO component plug, and

P-FU cartridge fuse plug can be used in the universal plug-in zone of the dis-connect

terminal block.

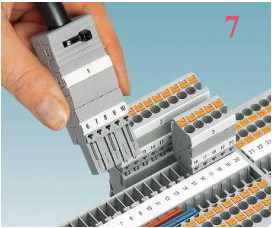

5.A test plug with a 2.3 mm diameter is available for measuring lines. All measure-ment and

test work can be completed at speed using test adapters for 4 mm diame-ter test plugs and

the modular test plugs.

6.As well as offering a testing facility in the double function shaft, all push-in

technology terminal blocks offer an additional test con-tact for test plugs with a 2.3 mm

diameter.

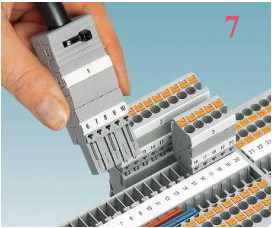

7.Push-in COMBI terminal blocks are avail-able for the plug-in configuration of signal

wiring. The system is touch-proof and offers self-assembly plugs with extensive accesso-

ries.

8.Auto flat-type fuse terminal blocks with a 4 mm2 conductor connection are available in

the same shape as the feed-through ter-minal blocks. All terminal blocks can be con-

tinuously bridged with one another with the double function shaft.

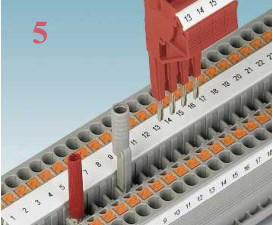

9.The compact lever-type fuse terminal blocks are of the same shape as the feed-through

terminal blocks and can be labeled and bridged continuously. A time-saving po-tential

distribution is easily created using a jumping bridge.

1: High-strength spring

2: Copper conductive strip

3: Imported flame-retardant nylon PA66

Ready for Automation

The modern and uniform design of the PUSH IN products already offers many advantages in wiring and testing. But tool-less connection and a consistent design are also important for the automated assembly and wiring processes of the future. These factors are already taken into account in our PUSH IN products. For example, the housing contour of our A-Series modular terminal blocks is already designed for automatic mounting rail assembly. The straight edges provide a secure hold for the gripper of a robot arm. PUSH IN connections are therefore easier to handle than other connection methods, even for automatic wiring machines.