Description

The PT6-4-G Terminal Block is a reliable and compact electrical connector designed for safe, efficient wiring. Its push-in connection technology allows tool-free cable insertion, ensuring faster installations. Made from flame-retardant materials and high-quality copper, it guarantees safety and performance, even in the most demanding environments. Certified for use in railway, shipbuilding, and explosion-proof applications, this versatile terminal block meets IEC standards and is ideal for any industrial setting.

Product Overview

The PT6-4-G Terminal Block is a top-tier solution for earthed and grounded electrical connections. With its compact design and push-in technology, it provides a safe and quick connection without the need for tools. Compatible with a 35mm DIN rail and various accessories, this terminal block is designed for easy integration into a variety of industrial applications. It offers corrosion resistance and vibration stability, making it perfect for harsh environments.

Product Features

Material Composition

Constructed from flame-retardant Nylon PA 66 and durable copper metal, the PT6-4-G Terminal Block ensures safety and long-lasting performance, even in extreme environments.

Tool-Free Wiring

With push-in connection technology, this terminal block allows you to quickly and easily connect cables without the use of tools, significantly reducing installation time.

Compact Design

The compact structure and front-entry connection enable wiring in tight spaces, making it ideal for applications where space is limited.

DIN Rail Mounting

The terminal block is equipped with a universal foot that fits standard 35mm DIN rails, ensuring secure and easy mounting.

Accessory Compatibility

Compatible with a variety of accessories including end covers, stoppers, marker strips, and plug-in bridges, allowing flexible configuration and potential distribution.

Vibration and Shock Resistant

Certified according to EN 50155 railway standards for vibration resistance and shock-resistance for shipbuilding applications, this terminal block offers high durability under harsh conditions.

Corrosion Resistant

The PT6-4-G Terminal Block is designed to resist corrosion, ensuring a long lifespan in industrial and outdoor environments.

Explosion Safety Certification

It is certified for enhanced safety in explosion-prone (Ex e) environments, making it a reliable choice for hazardous locations.

Basic Information

SMICO ID | PT6-4-G |

| Pitch | 8.2mm |

| Number of levels | 1 |

| Number of connections | 4P |

| Connection method | Push in spring terminal |

| Protection Level | IP20 |

| Work temperature | -40~+105℃ |

IEC Data

| Rated Current | 41A |

| Rated Voltage | 1000V |

| Overvoltage category | Ⅲ |

| Pollution degree | 3 |

| Rated impulse voltage | 8KV |

| Conductor cross section solid | 0.5-10mm² |

| Conductor cross section flexible | 0.5-6mm² |

| Conductor cross section flexible,with furrule | 0.5-6mm² |

| Stripping length | 10-12mm |

UL Data

| Use group | B | C | D |

| Rated Current | 40A | 40A | - |

| Rated Voltage | 600V | 600V | - |

| Rated cross section | 24-10AWG | - | - |

Material Date

| Insulation material | PA66 |

| Insulation material group | Ⅲa |

| Flame retardant grade, UL94 compliance | V0 |

| Contact material | Copper alloy |

| Surface characteristics | Sn,Plated |

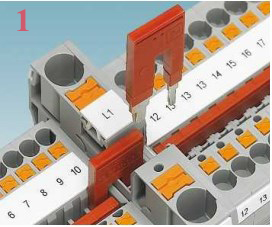

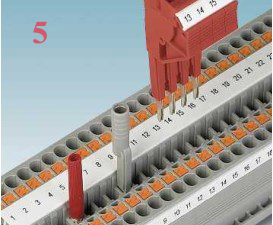

1.The reducing bridge allows terminal blocks with different nominal cross sections to be connected with

ease, e.g., a PT 10 push-in terminal block to a PT 2,5. Power blocks can be created quickly using the re-

ducing bridge.

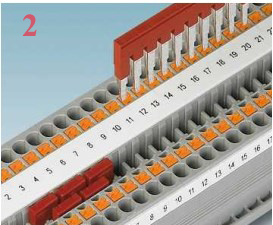

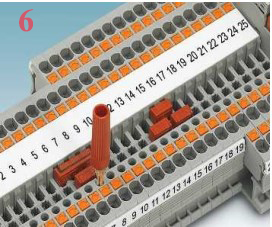

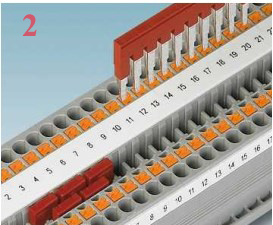

2.The double function shaft can be used to connect any number of terminal blocks with two-position bridges.

The 2 to 50-pos.bridges allow up to 50 terminal blocks to be bridged in one step.

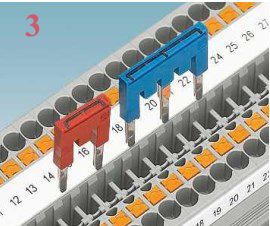

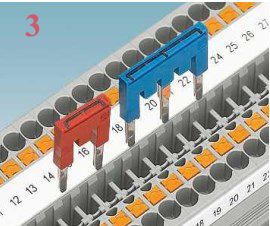

3.A jumping bridge is created by removing individual contact guides from the standard bridge. Two

potentials can then be routed in parallel. The contact points can also be marked.

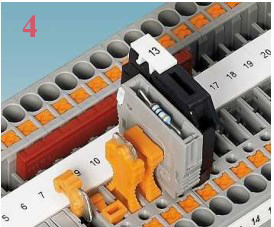

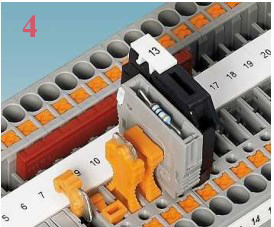

4.The P-FIX isolated feed-through connec-tor, P-DI isolating plug, P-CO component plug, and P-FU cartridge

fuse plug can be used in the universal plug-in zone of the dis-connect terminal block.

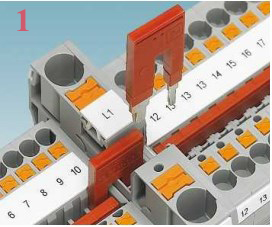

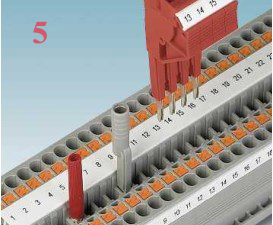

5.A test plug with a 2.3 mm diameter is available for measuring lines. All measure-ment and test work can

be completed at speed using test adapters for 4 mm diame-ter test plugs and the modular test plugs.

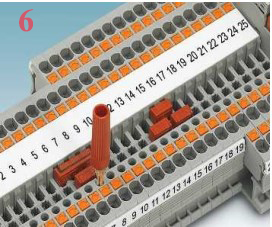

6.As well as offering a testing facility in the double function shaft, all push-in technology terminal

blocks offer an additional test con-tact for test plugs with a 2.3 mm diameter.

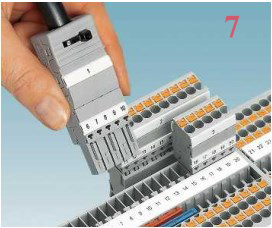

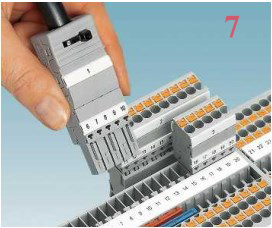

7.Push-in COMBI terminal blocks are avail-able for the plug-in configuration of signal wiring. The system

is touch-proof and offers self-assembly plugs with extensive accesso-ries.

8.Auto flat-type fuse terminal blocks with a 4 mm2 conductor connection are available in the same shape as

the feed-through ter-minal blocks. All terminal blocks can be con-tinuously bridged with one another with

the double function shaft.

9.The compact lever-type fuse terminal blocks are of the same shape as the feed-through terminal blocks and

can be labeled and bridged continuously. A time-saving po-tential distribution is easily created using a

jumping bridge.

1: High-strength spring

2: Copper conductive strip

3: Imported flame-retardant nylon PA66

In-line terminal blocks, PT combined terminal blocks, high current terminal blocks

With the in-line connection technology, wires with a diameter of 0.25 mm or more can be easily connected directly without tools. With contact springs, the wires can be inserted easily and the connection quality is high.

Advantage

With direct plug-in connection, the pre-treated rigid wire can be connected without tools, saving time

Easily insert wires, saving 50% of effort

The pull button is color-coded to ensure safe wiring and operation

No need to install tools, you can easily release the wire

Unified complete system accessories to reduce logistics costs

Push-in terminal blocks are part of the line system

PT combined terminal block

The in-line connection PT series terminal blocks are suitable for connecting various wires with a nominal wire diameter of 1.5 mm to 185 mm.

Just insert a rigid wire with a wire diameter of 0.25 mm or more or a flexible wire with a cold head into the wiring position, and the wiring is convenient and quick. The contact spring opens automatically, generating sufficient pressing force on the current bar. When installing a thin wire with a wire diameter of 0.14 mm? or more, use a standard screwdriver to unscrew the contact spring.

This series of terminal blocks takes full advantage of the complete system. Various connection technologies and standardized system accessories can be freely combined.

PTV combines the advantages of in-line self-locking technology and screw terminal blocks

The PTV terminal block combines the advantages of tool-free in-line self-locking connection and side access of screw terminal blocks. The terminal adopts the tool-free direct insertion self-locking connection technology, the required wire insertion force is small, the connection is strong in vibration resistance, and the wiring time is saved. In addition, it also adopts the side entry design, the wiring position is clear, and there is no bending radius. Thereby, the vertical wiring between the wiring terminal and the line trough is realized, and it is easier to paste and read the cable identification.

Detailed explanation of in-line connection technology

You can directly connect rigid wires or prefabricated wires with ferrules without tools.

The special spring design can easily insert rigid wires with a wire diameter of 0.25 mm or more and flexible wires with a cold press head to achieve a strong wire pull-out force.

Easily insert wires, saving 50% of effort.

By using the pull-out button, you can use various tools to loosen the wire without directly touching the live parts.

When connecting a flexible wire with a wire diameter of 0.14 mm or more without a ferrule, you only need to easily turn on the pull-out button when inserting it.

The pull button is color-coded to ensure safe wiring and operation.

Front wiring, easily connect various wires.

How to Maintain the PT6-4-G Terminal Block

To ensure long-lasting performance of your PT6-4-G Terminal Block, follow these maintenance tips:

Regular Inspection: Check for any signs of wear, corrosion, or damage on both the housing and connections.

Cleaning: Clean the terminal block periodically to remove dust and debris, especially around the connection points, using a soft, dry cloth.

Tightening Connections: Ensure that all connections remain tight and secure over time, especially in environments with vibrations.

Environmental Protection: If the terminal block is installed in a harsh environment, consider adding protective covers to further shield it from moisture, dirt, or corrosive substances.

Accessory Care: Inspect accessories such as marker strips and plug-in bridges regularly to ensure their functionality.

FAQs

Q: What type of cable sizes does the PT6-4-G Terminal Block support?

A: The terminal block is designed to support a wide range of conductor cross-sections, making it versatile for various cable sizes.

Q: Is the PT6-4-G Terminal Block suitable for outdoor use?

A: Yes, with its corrosion-resistant design and high durability, the PT6-4-G is suitable for outdoor and harsh industrial environments.

Q: Can the terminal block be used in explosive environments?

A: Yes, it is certified for use in Ex e environments, providing enhanced safety in explosion-prone areas.

Q: How is the terminal block mounted?

A: The PT6-4-G Terminal Block is designed for DIN rail mounting and can be easily installed on standard 35mm rails.

Q: What standards does this terminal block comply with?

A: The PT6-4-G Terminal Block complies with the IEC 61109 standard, ensuring top quality and safety in industrial applications.