Description

The PCFS-OD6.0 Heavy Duty Pneumatic Connector is designed for industrial applications, featuring nickel-plated brass contacts for durability and enhanced performance. With a 6.0mm pneumatic contact, it ensures efficient compressed air transmission.

Product Overview

The PCFS-OD6.0 Heavy Duty Pneumatic Connector offers a durable solution for industrial compressed air applications. Featuring nickel-plated brass contacts, it ensures robust performance and longevity. Designed for high-pressure environments, the connector supports up to 10 bar of constant pressure, making it ideal for flexible production setups. With a 6.0mm pneumatic contact size, it provides optimal airflow and easy integration with various pneumatic systems. This connector is a versatile addition to SMICO’s modular series, supporting both pneumatic and electrical modules for maximum application flexibility.

Product Features

Durable Construction: Nickel-plated brass contacts ensure long-lasting performance.

High-Pressure Compatibility: Can withstand up to 10 bar of constant pressure.

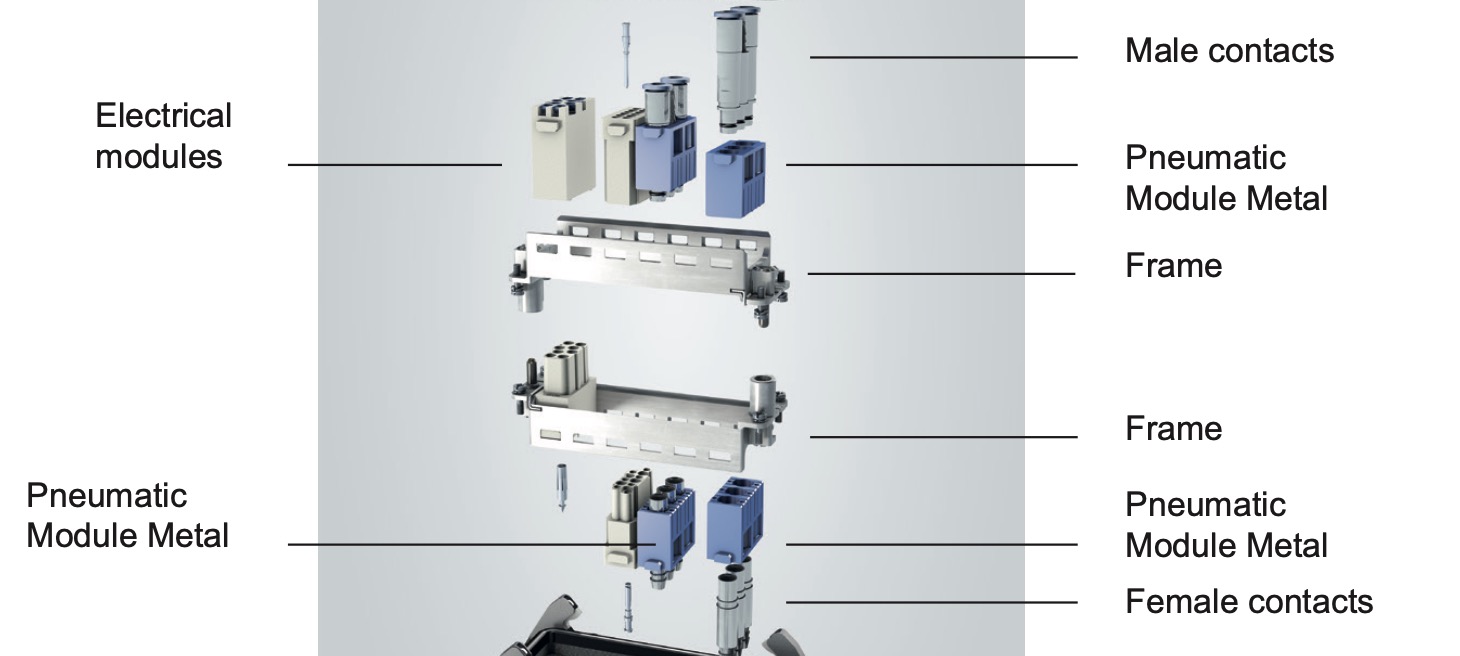

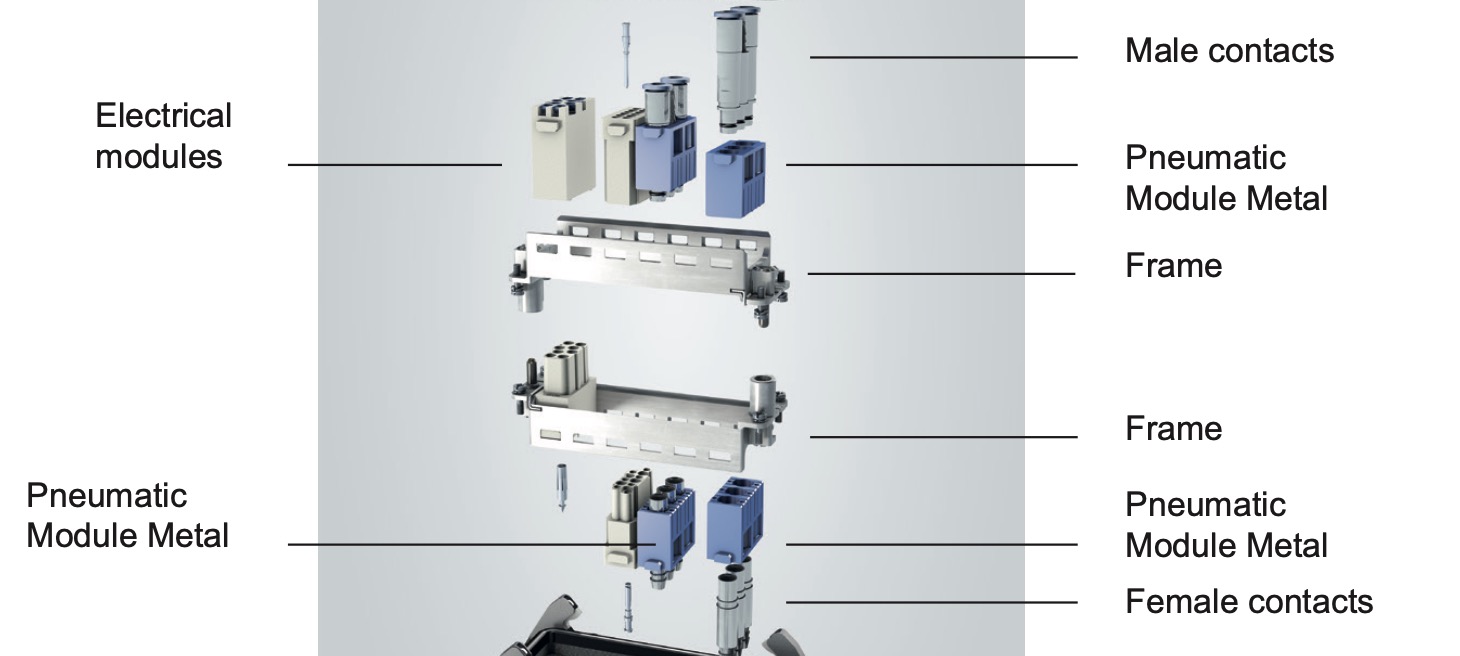

Versatile Module System: Part of SMICO’s modular series, compatible with various connector configurations.

Flexible Airflow: 6.0mm pneumatic contact enables efficient compressed air transmission.

Compact Design: Angled contacts provide space-efficient wiring and easier integration.

Wide Compatibility: Works with various housings, including Eco, Yellock, HA, and HB.

Product Description

Introduction to PCFS-OD6.0 Heavy Duty Pneumatic Connector

The PCFS-OD6.0 Heavy Duty Pneumatic Connector is engineered to meet the demands of modern industrial applications, where reliability and high performance are paramount. Featuring a robust nickel-plated brass construction, this connector is designed for transmitting compressed air in high-pressure environments, withstanding up to 10 bar of constant pressure. This capability makes it ideal for flexible production environments where pneumatic systems need to be frequently reconfigured.

The connector is part of SMICO’s versatile modular series, allowing it to be combined with other electrical and pneumatic modules to create custom configurations. The 6.0mm pneumatic contact ensures efficient airflow and consistent performance across a wide range of industrial applications, including power drives, control systems, and automation devices.

Optimized for High-Pressure Environments

With the ability to handle a constant pressure of 10 bar, the PCFS-OD6.0 outperforms many standard connectors, making it suitable for a wide range of industrial systems that require reliable compressed air transmission. Its nickel-plated brass contacts are designed for long-term durability, providing excellent resistance to wear and corrosion even in demanding settings.

In comparison to earlier models, which could handle up to 8 bar, this new version expands the range of applications for pluggable compressed air distribution, making it an excellent choice for industries that rely on high-efficiency pneumatic systems.

Space-Efficient and Flexible Design

One of the key features of the PCFS-OD6.0 is its space-saving design. The angled contacts offer more room for wiring within the connector housing, reducing the risk of malfunctions due to tight spaces. This design also simplifies the assembly process, particularly in situations where wiring space is limited.

Additionally, the pneumatic contacts are equipped with push-in connection technology, making installation and maintenance straightforward and hassle-free. This ensures that the connector can be easily integrated into existing systems without requiring extensive modifications.

Versatile Application Across Industries

The PCFS-OD6.0 is compatible with various connector housings, including the Eco, Yellock, HA, and HB models, providing flexibility across different industrial settings. Whether it’s used in manufacturing, automation, or electrical systems, this pneumatic connector meets the high standards required for efficient compressed air transmission. With its modular capability, users can create custom configurations that combine both electrical and pneumatic functions, streamlining installation and improving overall system performance.

FAQs

Q: What is the maximum operating pressure of the PCFS-OD6.0 connector?

A: The connector can handle up to 10 bar of constant pressure, making it ideal for high-demand pneumatic applications.

Q: Are the contacts resistant to corrosion?

A: Yes, the contacts are nickel-plated brass, providing excellent corrosion resistance and ensuring long-lasting durability.

Q: Can this connector be used in systems with limited wiring space?

A: Absolutely. The angled contacts are specifically designed to save space, making the connector suitable for compact or confined systems.

Q: Is the PCFS-OD6.0 compatible with other SMICO modules?

A: Yes, this connector is part of SMICO’s modular series and can be combined with other pneumatic and electrical modules for versatile configurations.

How to Maintain

Regular Inspection: Periodically check the connector for signs of wear or corrosion, particularly in high-pressure environments.

Cleaning: Wipe the connector with a clean, dry cloth to remove any dust or debris. Avoid using harsh chemicals that could damage the nickel-plated brass.

Check Air Pressure: Ensure the pneumatic system's pressure stays within the recommended range (up to 10 bar) to prevent overloading the connector.

Tighten Connections: Over time, the connections may loosen due to vibrations or mechanical stress. Tighten them as needed to maintain a secure and reliable connection.

Replace Worn Contacts: If any contacts become damaged or corroded, replace them promptly to avoid performance issues and ensure the connector operates efficiently.

By following these maintenance steps, the PCFS-OD6.0 Heavy Duty Pneumatic Connector will continue to deliver reliable performance, ensuring smooth operation across your industrial systems.

Pack contents

The SMICO Pneumatic Module Metal has room for 3 contacts with connections for - Tubes with inner diameter (ID) = 3.0, 4.0 or 6.0 mm

- Tubes with outer diameter (OD) = 3.0, 4.0 or 6.0 mm

At least two modules are required for each plug-in connection, and in addition:

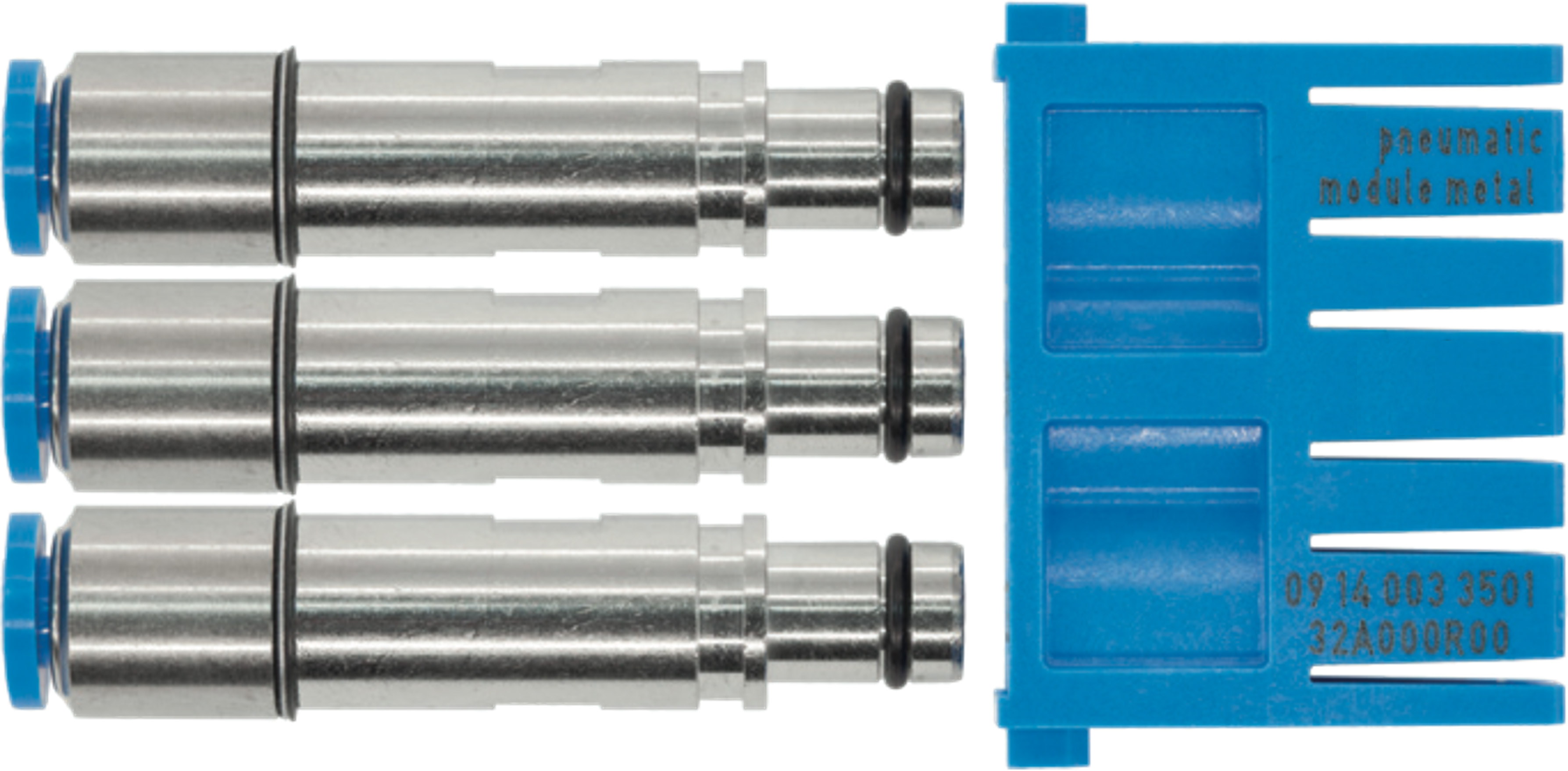

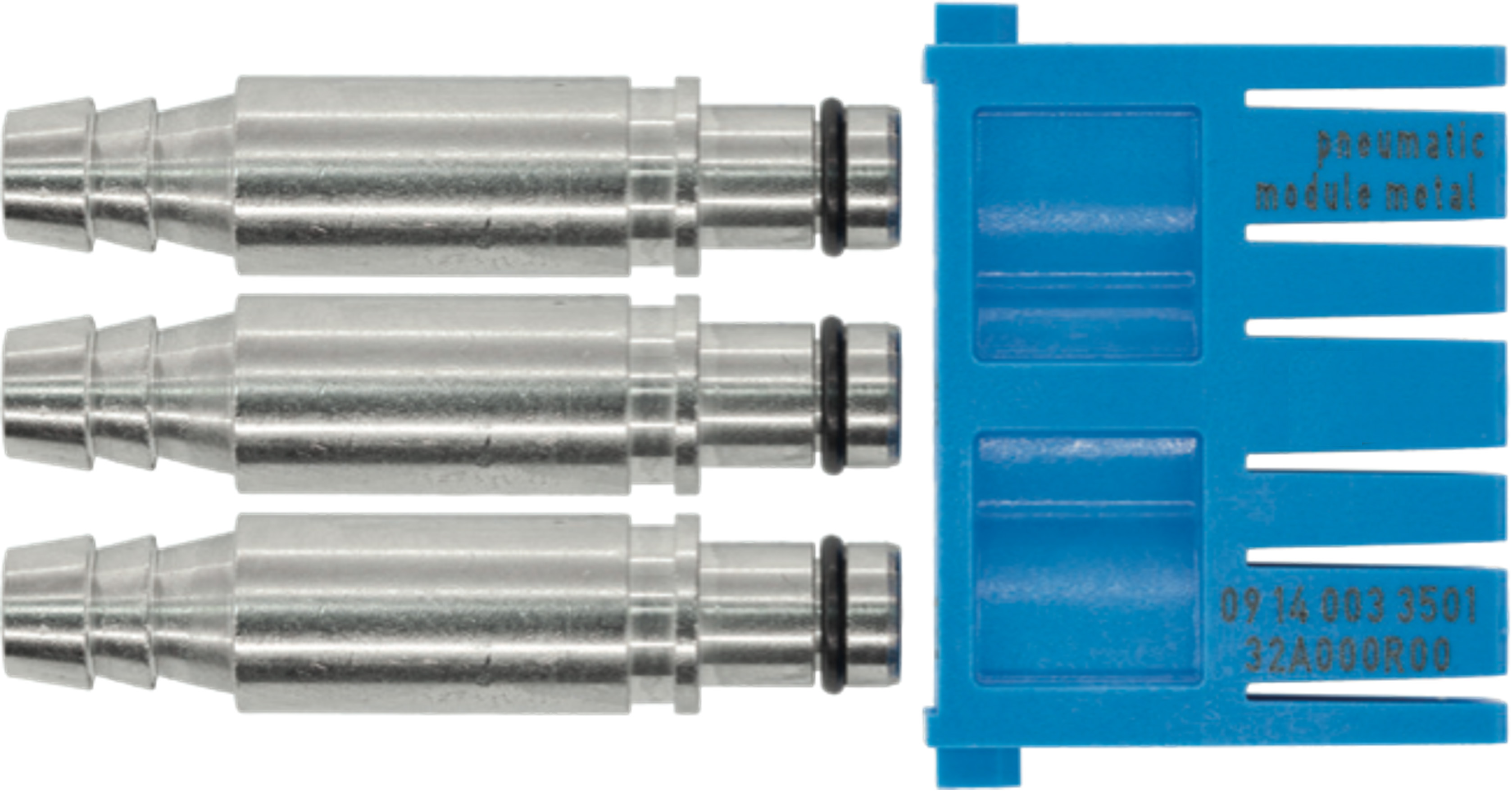

• Han® Pneumatic male contact for ID = 3.0, 4.0 or 6.0 mm / (OD) = 3.0, 4.0 or 6.0 mm (10 pieces per pack)

• SMICO Pneumatic female contact for ID = 3.0, 4.0 or 6.0 mm / (OD) = 3.0, 4.0 or 6.0 mm (10 pieces per pack)

The female contact is available in versions with or without the shut-off function.

Please note the following when determining your order:

• The connecting profile of the contacts used in the SMICO Pneumatic Module Metal are either designed for the hose inner or outer diameter.

Users must select the appropriate versions and dimensions for the housing and mounting frame according to the requirements of their connector applications.

The components needed by users to build pluggable systems for compressed air distribution can be found in the SMICO Pneumatic Module Metal and accessories table.

Identificatio | M/F | Part no. | Ø |

SMICO Pneumatic Module Metal | M/F | 09140033501 | 3/4/6mm |

Male ID contact Female ID contact | M F | 09140006303

09140006403 | 3 mm |

Male OD contact Female OD contact | M F | 09140006353 09140006453 | 3 mm |

Male ID contact Female ID contact with shut-off | M F | 09140006303 09140006413 | 3 mm |

Male OD contact Female OD contact with shut-off | M F | 09140006353 09140006463 | 3 mm |

Male ID contact Female ID contact | M F | 09140006304 09140006404 | 4 mm |

Male OD contact Female OD contact | M F | 09140006354 09140006454 | 4 mm |

Male ID contact Female ID contact with shut-off | M F | 09140006304 09140006413

| 4 mm |

Male OD contact Female OD contact

with shut-off | M F | 09140006354 09140006464 | 4 mm |

Male ID contact Female ID contact | M F | 09140006306 09140006406 | 6 mm |

Male OD contact Female OD contact | M F | 09140006356 09140006456 | 6 mm |

Male ID contact Female ID contact with shut-off | M F | 09140006306 09140006416 | 6 mm |

Male OD contact Female OD contact with shut-of | M F | 09140006356 09140006466 | 6 mm |

C contact adapter | M F | 09140006391 09140006491 |

|

Contact lubricant |

| 0999000829 |

|

General information

SMICO modular connectors meet the requirements for safety and testing as detailed in DIN EN 60 664-1 and DIN EN 61 984. The safety of modular connectors can be first ascertained when they are actually in the application (e.g. after the individual components have been selected and assembled together). This chapter defines the proper and intended usage of Han® Pneumatic Modules. It also provides general safety instructions for using the modules in the SMICO Modular connectors.

Proper and intended use

The SMICO Pneumatic Module Metal shall be used to transmit properly prepared compressed air in a Han-Modular® industrial connector. The module is suitable for use in pneumatic systems which have an operating pressure not exceeding 10 bar. Any other usage must be first agreed upon with SMICO.

General safety information

The following safety instructions must be followed during the installation, servicing and removal of Han-Modular® connectors (including the SMICO Pneumatic Module):

Requirements for installation

All work that is related to installation, maintenance and removal of the SMICO Modular connectors must be performed by qualified, trained staff. If electrical modules are being used within the EU, this work must be carried out by qualified personnel in accordance with DIN EN 50110-1/-2 and IEC 60364. The relevant national accident prevention regulations must also be observed.

Never plug or unplug while under voltage or load

SMICO Modular connectors must never be plugged in or unplugged while electrical voltages or loads are applied. This prohibition does not apply if the connector contains only pneumatic modules.

Protection against electric shock

SMICO Modular connectors are designed for over-voltage category III (DIN EN

60 664-1). Users must ensure that the connector is properly installed to protect against electric shock. This protection can be ensured by using the hoods and housings provided by SMICO or by other measures that the user takes during the installation.

Only suitable for compressed air

The SMICO Pneumatic Module Metal is only suitable for the transmission of dry, properly prepared compressed air. Do not use valves or sockets from the SMICO Pneumatic Module Metal for transmitting other media such as other gases or liquids. Any usage that deviates from this purpose is not permissible unless it has been clarified with the relevant national associations for electrical engineering (e.g. in Germany: the VDE Association for Electrical, Electronic & Information Technologies or its regional organisations).

Permissible degree of pollution/contamination

SMICO Modular connectors are designed by default for pollution degree 3. All SMICO industrial connectors with IP54 protection or higher (IP protection classes according to DIN EN 61 984, section 6.19.2.3) comply with this pollution degree. Even connectors with a lower IP protection class are suitable for use as pollution degree 3 when they are equipped with a cap that provides them with IP54 or higher while disconnected.

Technical description

Module and contacts

The SMICO Pneumatic Module Metal is used to create pluggable connections for transmitting dry, properly prepared compressed air in pneumatic systems.

The female contact is available in versions with or without the shut-off function. In the shut-off version, a spring-loaded valve closes over an O-ring when the connector is opened. This prevents compressed air from escaping. When plugged in, the male contact presses against the valve and keeps the contact open.

Module Number of contacts Colour

Material

Limiting temperatures Flammability acc. to UL 94 Mechanical working life | 3

Blue

Polycarbonate

-20 °C ... +80 °C

V0

≥ 10,000 mating cycles |  |

Contacts Material

Colour

Hose connection

- Inner diameter (ID)

Operating pressure

|

Stainless steel Metallic

- 3.0 mm

- 4.0 mm (1/8") - 6.0 mm 10 bar (145 psi) |  |

Seals Material |

|

|

Shut-off valve Material |

|  |

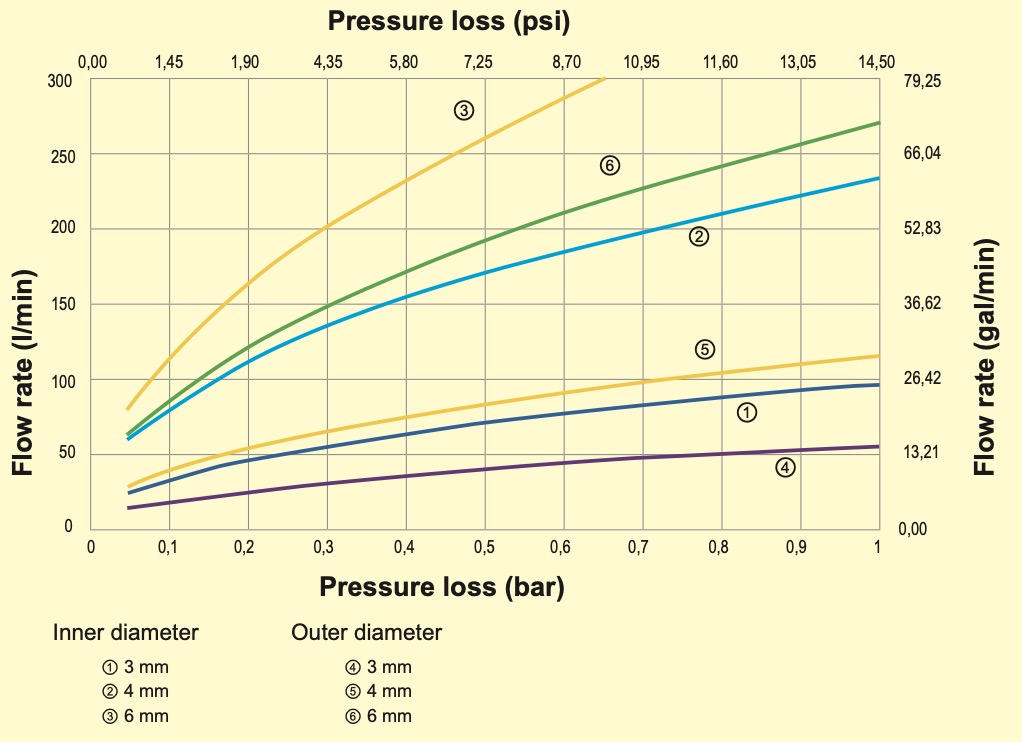

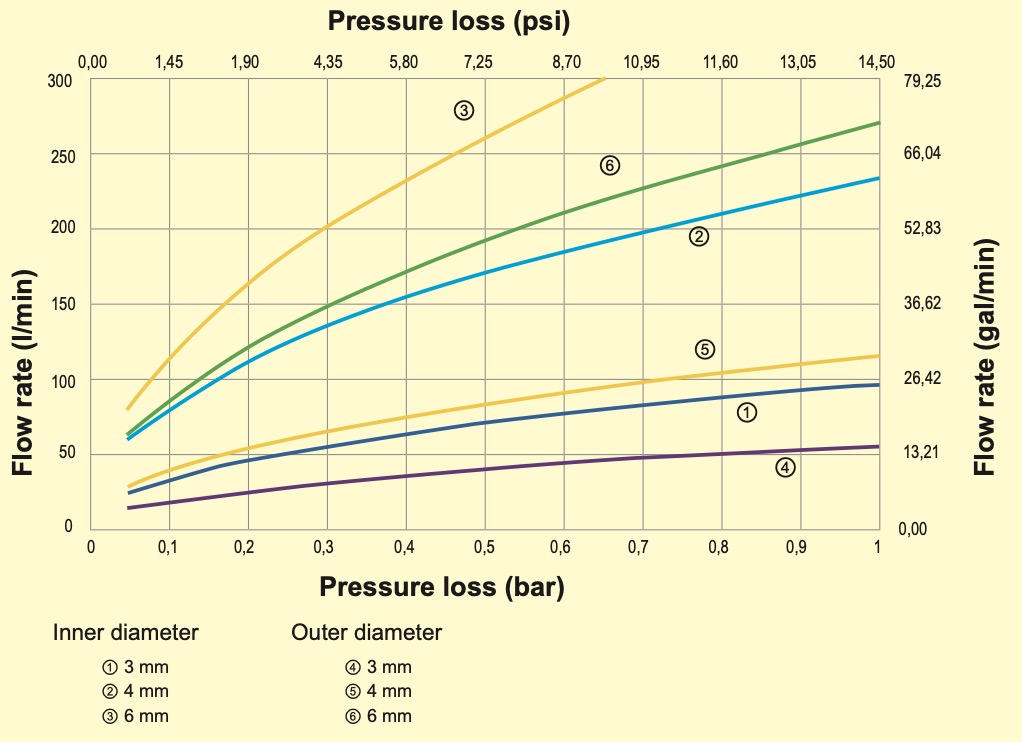

Flow rate and pressure drop across the contact

To assist designers and planners as they select and dimension their compressed air systems, SMICO has determined the maximum flow rate, the pressure drop for the contacts of the SMICO Pneumatic Module Metal.

Flow rate

The flow rate specifies the air volume that can be passed through the contacts of the SMICO pneumatic Module Metal. The ratio between the prevailing air volume (l/min) and the resulting pressure drop (bar) is shown. This ratio is used to calculate the flow rates for the various SMICO Pneumatic Metal contacts, as shown in Table 7. The flow rates were determined for the female contacts with a non-return valve.

Figure 1: Max. flow rate for pneumatic contacts with shut-off

Figure 2: Comparing a female module with/without the shut-off valve

Allowed hoods and housings

The MICOS Pneumatic Module Metal can be used with a variety of SMICO hoods and housings. An additional mechanism is needed for some hoods/housings in order to install the SMICO Modular modules (e.g. the H10A).

The high construction types of hoods and housings are normally recommended forpneumatic applications. This construction type simplifies the cabling of the modulesconsiderably; there is no need to excessively bend the pneumatic hoses. If OD female contacts with a valve are used in a bulkhead surface-mounted housing, the pneumatic contacts with angled outlets must be selected. When selecting the hoods/ housings, make sure that the bending radii of the pneumatic hoses match their respective installation situations.

Type of hood/ housing | Sizes | Number of possible modules |

Astandard | 10A | 1 |

Bstandard | 6B/10B 16B/24B 32B/48B | 2/3/4/6/8/12 |

EMC | 6B/10B 16B/24B | 2/3/4/6 |

M | 6B/10B 16B/24B 48B | 2/3/4/6/12 |

HPR | 6B/10B 16B/24B | 2/3/4/6 |

Eco | 6B/10B 16B/24B | 3/4/5/7 |

Yellock | 30/60 | 2/4 |

Snap | 6B/10B 16B/24B | 2/3/4/6 |

Modular Compact | - | 1 |

Modular Twin | - | 2 |

Termination techniques

The SMICO Pneumatic Module Metal is offered with two different termination techniques. The selection of the proper pneumatic hose is also very important.

The following information will help you to find the proper combination of pneumatic contact and pneumatic hose:

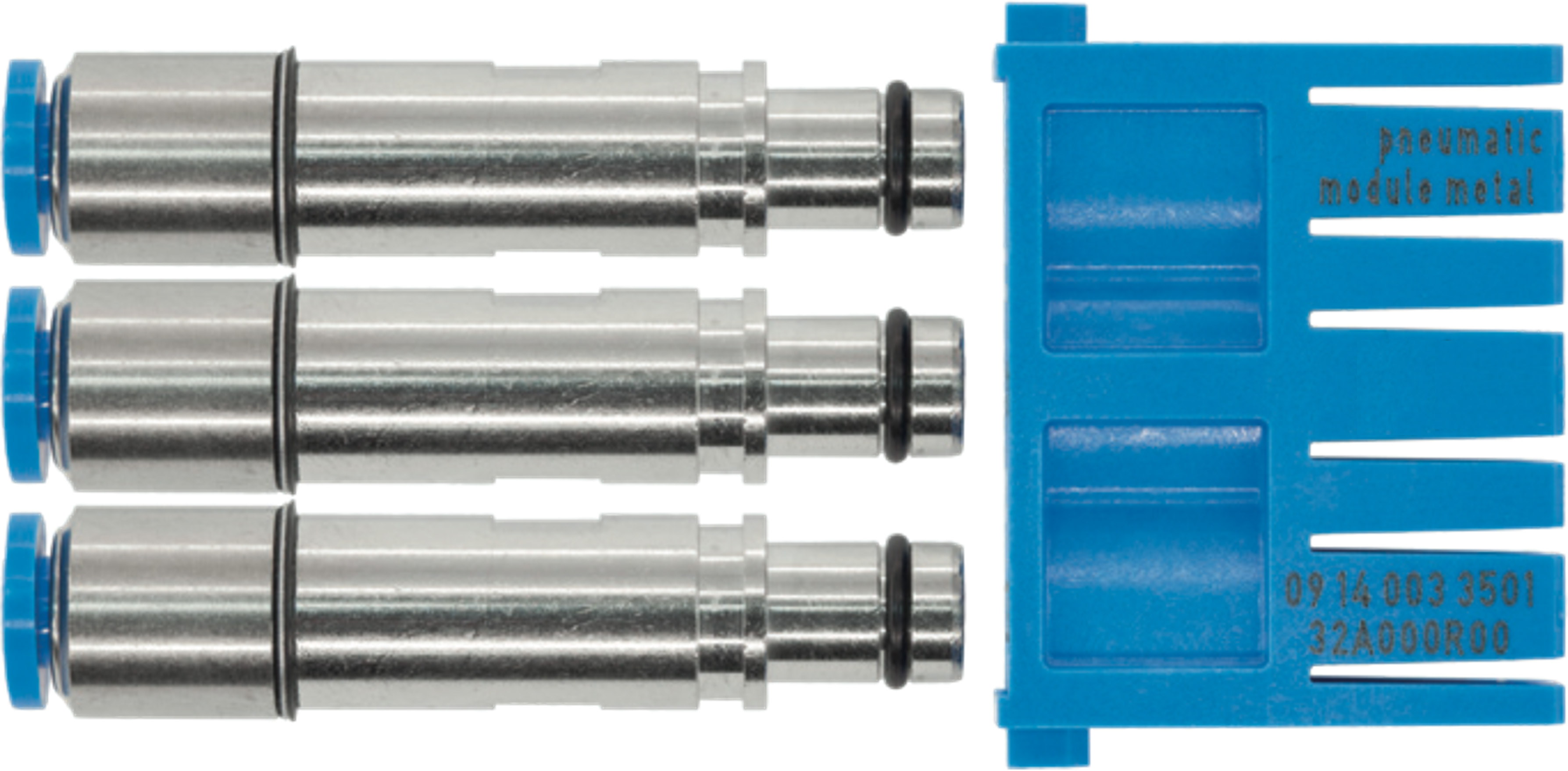

Push-In termination technique

The pneumatic hose is clamped over the calibrated outer diameter when using the Push-In termination technique. Thus, the pneumatic contact with this connection technique is called OD (e.g. Outer Diameter). This refers to the calibrated diameter of the hose.

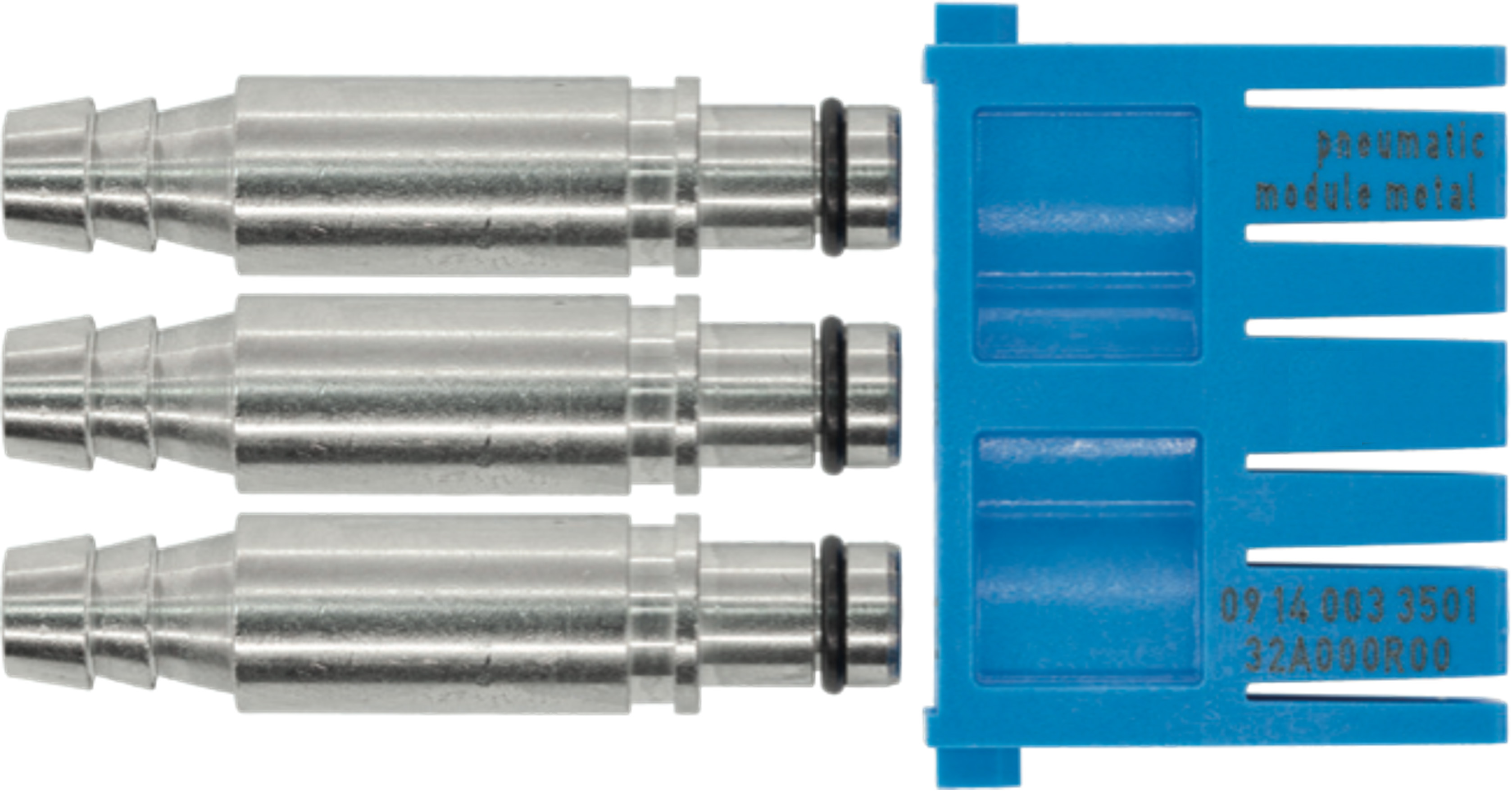

Termination technique using inner clamping

The inner clamping method for terminating involves pushing the pneumatic hose over the connecting surface of the pneumatic contact. Pneumatic hoses with a calibrated inner diameter should be used here. Thus, the pneumatic contact with this connection technique is called ID (e.g. Inner Diameter). This refers to the calibrated diameter of the hose.

Use of male and female guiding pins

For applying the SMICO Pneumatic Module Metal the use of male (part no. 09 14 000 9908) and female guiding pins (part no. 09 14 000 9909) is not necesseraily required. The reason is that the module can withstand an oblique lengthwise tilt of more

than ±5°, in accordance with DIN EN 175 301-801. However, the use of the male

and female guiding pins is still helpful when coding adjacent industrial connectors. Possible codings are shown in the table below (Figures 2 and 3).

Assembly instructions

Assembly

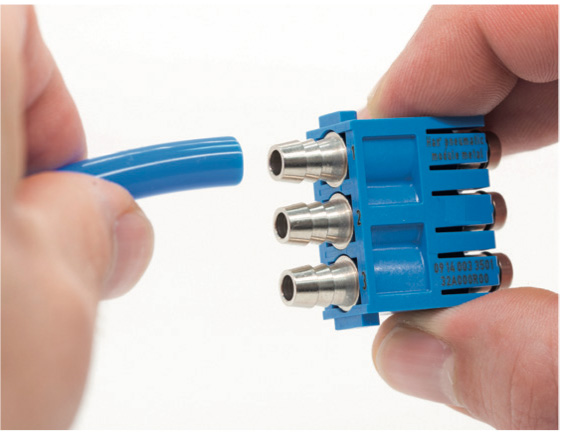

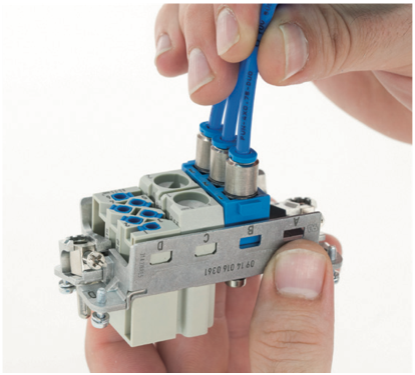

The assembly process is shown using an example of the SMICO Pneumatic Module Metal with three pneumatic OD contacts. The pneumatic ID contacts are assembled in a simi- lar fashion.

| Overview

- SMICO Pneumatic Module Metal - 3 male OD contacts |

| Overview

- SMICO Pneumatic Module Metal - 3 male ID contacts |

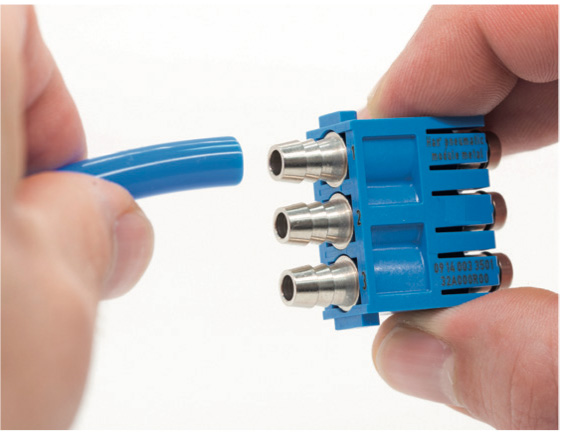

| Insert the pneumatic contact from the connection side into the pneu- matic module until you feel some resistance. Then press the contact forcefully until it snaps into the module. ► You will hear a click when the pneumatic contact is fully inserted into the module. ► The assembly of the pneumatic ID contacts is similar to the assembly of the pneumatic OD contacts |

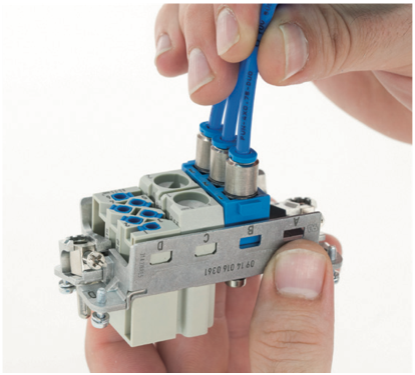

| Connect the pneumatic hose with the pneumatic contact. When using the Push-In termination, insert the hose all the way into the termination side of the contact. ► Pull gently on the hose to make sure it is securely attached |

| Connect the pneumatic hose with the pneumatic contact. When using the ID termination technique, push the hose onto the contact.

► Make sure that the end of the hose is protruding beyond the upper profile ring.

► Pull gently on the hose to make sure it is securely attached. |

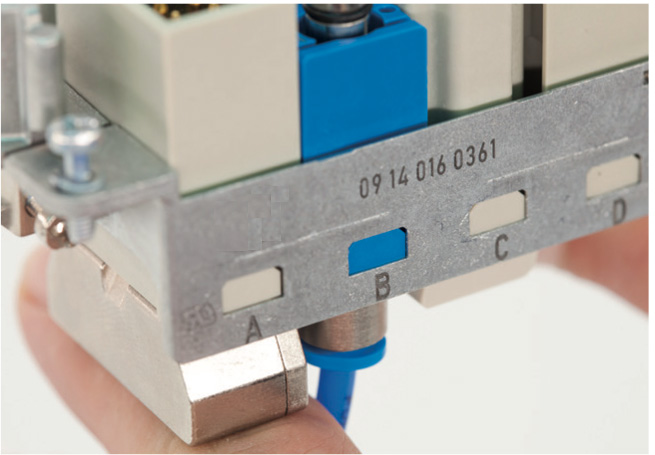

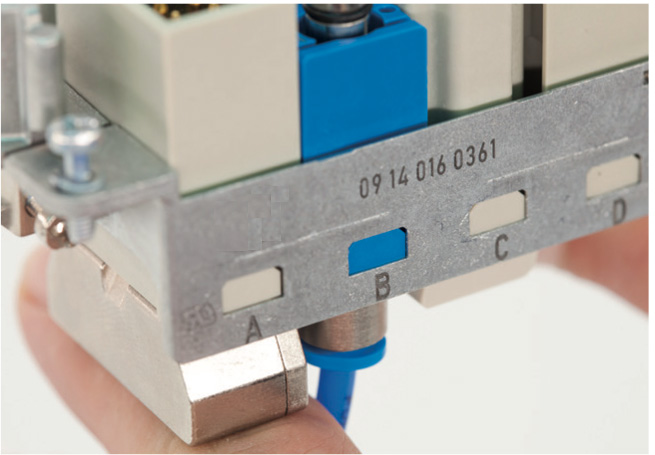

| You can now install the completely assembled Pneumatic module in the SMICO Modular Hinged Frame.

Open the hinged frame and then put the module in its proper position. ► Make sure that the module notches fit into the recesses of the hinged frame. |

| After you have completely loaded the Han-Modular® Hinged Frame, close it by gently pressing on the outer sides of the frame. ► Make sure that the module's notches fit precisely into the recesses of the hinged frame. |

| Slide the SMICO-Modular Hinged Frame into the hood/housing. ► Make sure that the hoses are properly guided through the cable gland. ► Use the four screws to mount the frame in the housing.

|

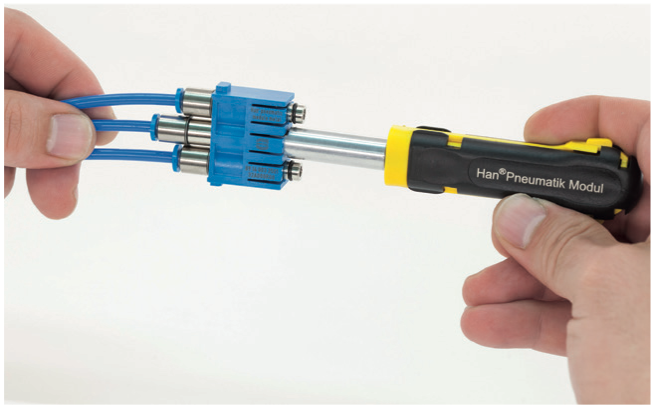

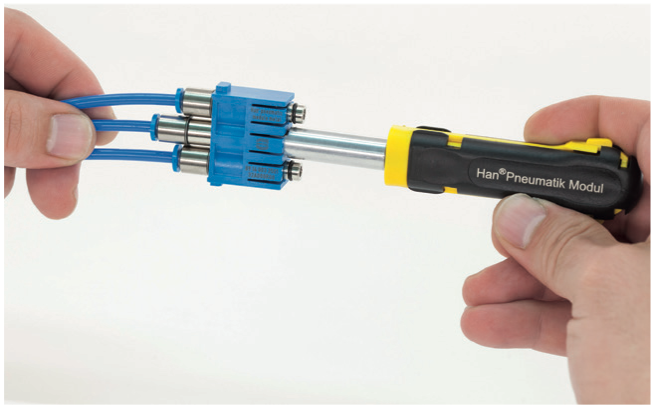

A specially designed removal tool is needed to remove the pneumatic contacts from the module.

| Part number: 09 99 000 089 |

| Insert the removal tool into the mating side of the Pneumatic module. ► The tool ̓s prongs must spread apart the module ̓s holding latches. |

| With the removal tool properly inserted, pull the contact out of the module. |

| In order to remove the pneumatic hose from a pneumatic contact that uses Push-In termination, press the contact's blue ring while pulling on the hose |

| In order to remove the pneumatic hose from a pneumatic contact that uses the ID termination technique, cut the hose along its gripping surface. The hose can then be removed from the pneumatic contact. |

Preventing malfunctions

Compressed air systems can become contaminated with solid particles, such as metal fragments, water, oils or grease. Such impurities can cause the pressure in the distribution system to drop. Leaks from hoses, contacts or valves can also cause pressure drops. Follow the operating and safety instructions for the compressed

air processing/distribution equipment closely (and also for the silencing equipment, where applicable). Also follow the safety instructions from the manufacturers of hoses, valves, and other coupling elements.