The SMICO-Modular series is designed for combining different Assembly details transmission media in one connector. The multifaceted system of inserts, contacts, frames, hoods and housings fulfils individual customer requirements. To continuously enable new configurations, the SMICO-Modular series growths constantly. More than 50 different modules for different transmission media are available. These cover various termination techniques.

The SMICO-Modular hinged frame enables the configuration of all modules in the well-accepted SMICO hoods and housings size 6B-48B. Further additional solutions are available, e.g. suitable docking frames for drawer units. Individual customer requirements can be realized. Combining various transmission media in one single connector results in lower expenditures in installation time and production downtime. Space savings and cost savings are further benefits. The easy extension possibilities secure a future safe design.

Features:

9-pin D-Sub connector of the SMICO-Modular system

Suitable for the transmission of sensitive signals

Compatible to crimp, solder or IDC termination

Flexible solutions according to specific customer requirements

Reduction of installation time and production downtimes

Space savings

Cost savings

Future safe design, easy extension

9 Poles,5A,Crimp male insert

Inserts | Suitable Shell: |

Number of contacts | 9 |

Electrical data acc. to EN 61 984 |

|

---Rated current | 5A |

---Rated voltage conductor | 50V |

---Rated impulse voltage | 0.8kV |

---Pollution degree | 3 |

---Pollution degree 2 also |

|

Rated voltage acc. to UL/CSA |

|

Insulation resistance | ≥1010Ω |

Material | polycarbonate |

Limiting temperatures | -40℃...+125℃ |

Flammability acc. to UL 94 | V0 |

Mechanical working life(mating cycles) | ≥500 |

Contacts |

Material | copper alloy |

Surface | hard-gold plated |

hard-silver plated |

Contact resistance |

|

terminal |

|

---Wrie gauge |

|

---AWG |

|

---Tightening/Test torque |

|

---Stripping length |

|

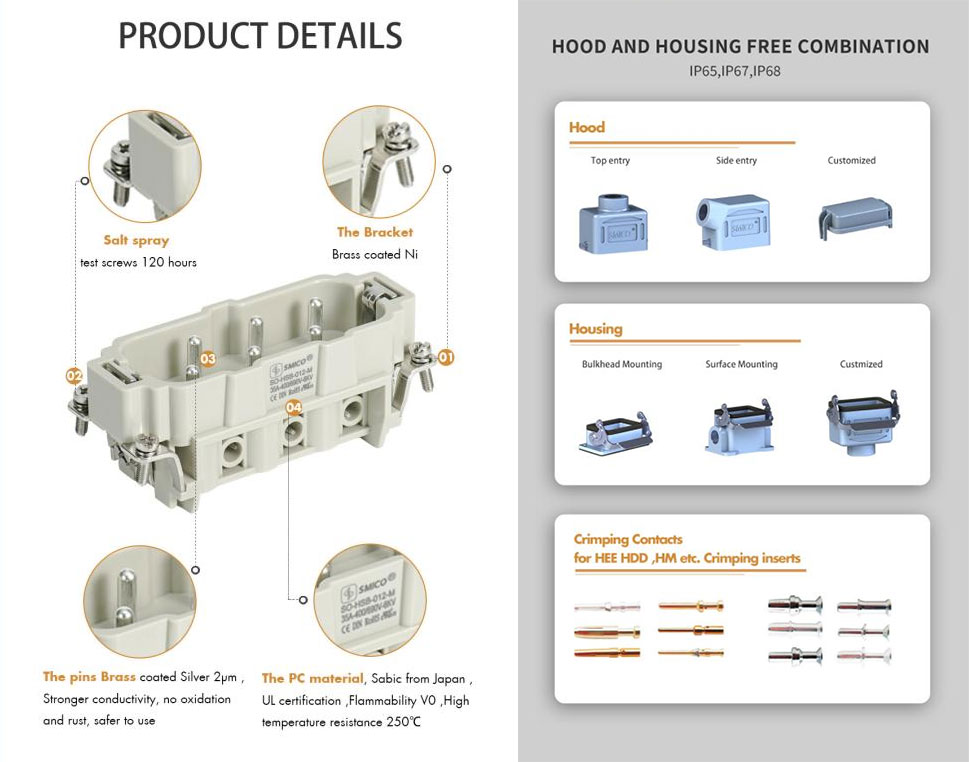

The function of the heavy-duty connector

1. Electrical insulation between connectors to avoid interference between signals.

2. Fix the position of the connector, which is conducive to plugging and unplugging and the stability of the position.

3. Provide mechanical protection and support for the insert body.

4. Separate the connector from the application environment, reduce environmental pollution and corrosion of the connector, and extend the service life of the connector.

The advantages of heavy-duty connectors

1. Realize pre-installation, pre-installation of a large number of complicated circuits, which can greatly improve the efficiency of equipment installation and reduce the rate of wiring errors.

2. The heavy-duty connector provides a highly integrated connection, and the abundant combination methods maximize the effective utilization of the equipment space.

3. Heavy-duty connector The connector conveniently and efficiently realizes the modular structure of each functional template block in the equipment, so that the equipment can be transported, installed, maintained and repaired conveniently and safely. Connectors are widely used in the field of power transmission and distribution.

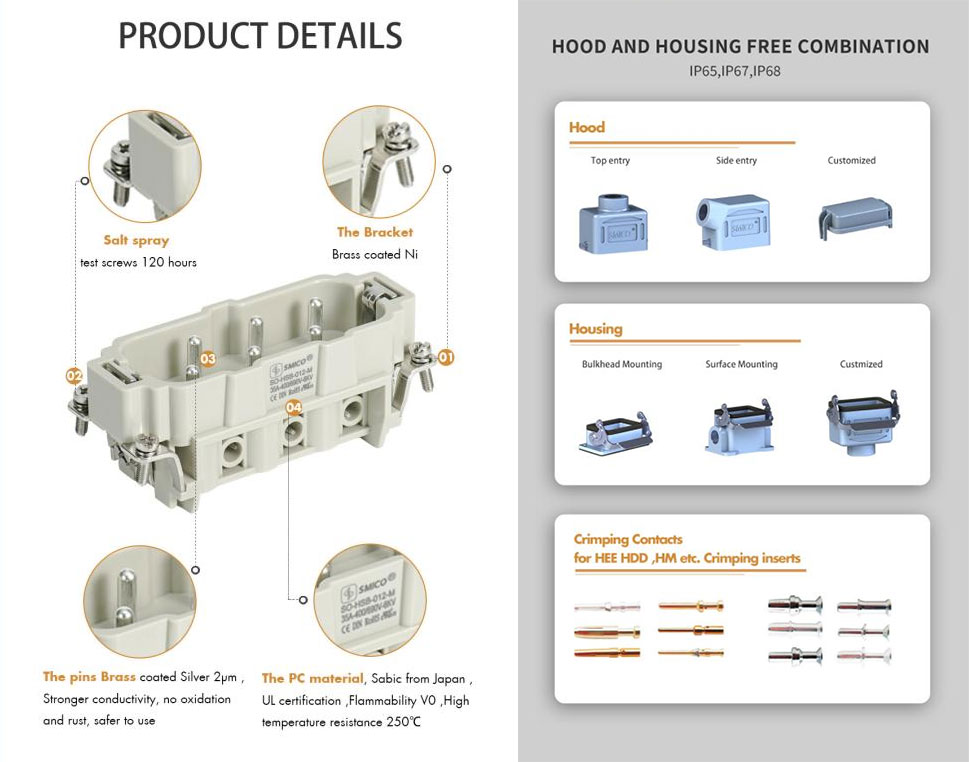

4. The high protection level (IP65, IP68) provided by the heavy-duty connector is incomparable to the advantages of the equipment connection system in the harsh environment. Provide effective protection in harsh environments such as sand, dust, rain, cold, ice and snow, and oil pollution.

heavy-duty connector wiring method

1. Loosen the screw with a screwdriver, put the wire into the side hole of the insert, and then tighten the screw.

2. To install the upper shell of the heavy-duty connector, use a screwdriver to unscrew the fixing screws of the insert, put the insert into the upper shell, and then tighten the fixing screws.

3. For the installation of the lower shell of the heavy-duty connector, use the same method to fix the lower shell, and insert the upper shell and the lower shell of the inserted body into each other.