Description

The HK-004/0-M Industrial Heavy-duty Connector is engineered to meet the rigorous demands of industrial environments. This aviation plug boasts exceptional durability and high voltage resistance, making it ideal for connecting a variety of electronic equipment and power supplies. With its reliable sealing and corrosion-resistant materials, this connector ensures stable and secure connections even in the most challenging conditions.

Product Description

Introduction

The HK-004/0-M Industrial Heavy-duty Connector is designed for extreme applications where reliability is paramount. Its advanced engineering ensures that it can withstand the toughest industrial conditions, making it an ideal choice for a variety of sectors, including manufacturing, robotics, and electrical control.

Superior Durability

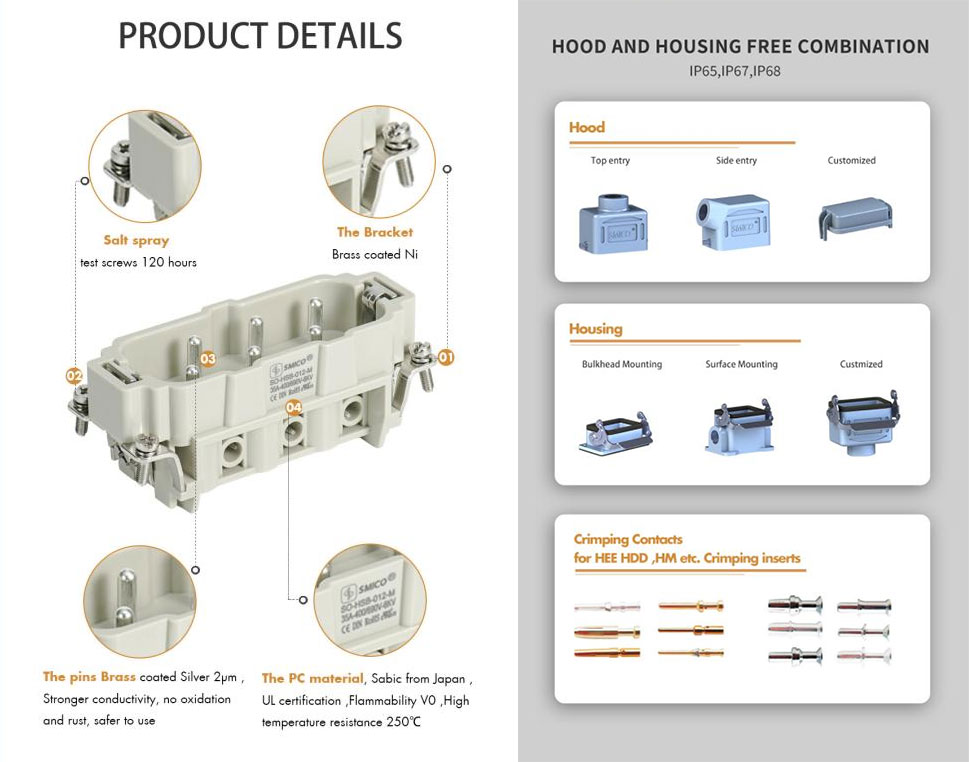

Constructed from high-quality die-cast aluminum alloy and self-extinguishing thermoplastic, this connector provides unmatched durability. The robust design ensures resistance to high mechanical stress, while the vibration-resistant features make it suitable for dynamic environments. Whether you're dealing with heavy machinery or intricate electronic setups, the HK-004/0-M guarantees a secure connection.

Waterproof and Corrosion-resistant

With its advanced sealing technology, this aviation plug offers excellent protection against dust and water ingress. The protective sealing ring is specifically designed to withstand corrosive substances, ensuring long-lasting performance in challenging environments. Whether used outdoors or in industrial settings, you can trust the HK-004/0-M to maintain integrity and performance.

Product Features

Robust Design: Perfect for severe industrial applications.

High Voltage Resistance: Handles up to 80A, accommodating high voltage needs.

Mechanical Strength: Built to withstand high stress and mechanical impacts.

Vibration Resistance: Designed to endure high-frequency vibrations.

Corrosion Resistance: Ideal for corrosive environments.

Strong Ethernet Connectivity: Ensures reliable network connections.

Wide Product Range: Supports over 6,000 compatible products.

AC and DC Compatibility: Versatile for both AC and DC applications.

Multi-pole Connectors: Perfect for various electronic setups.

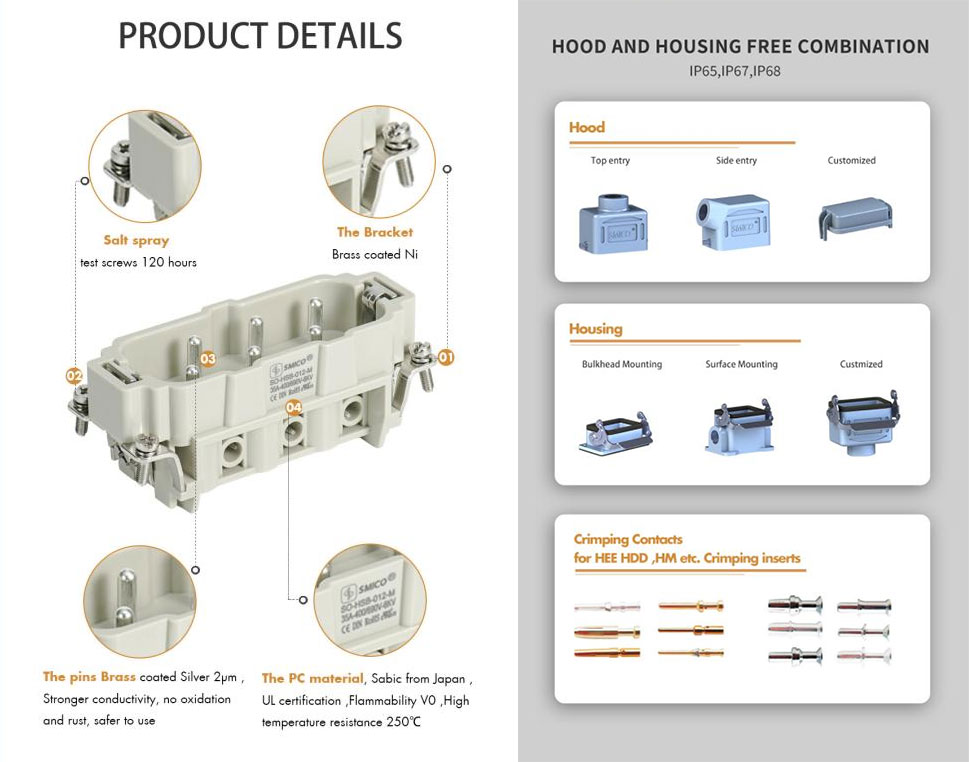

Environmental Covers: Available for standard, harsh, and EMC environments.

Durable Materials: Made from die-cast aluminum alloy and self-extinguishing thermoplastic.

Connection Stability: Features dual locking systems for secure connections.

Accidental Opening Protection: Ensures connections remain secure.

Protective Sealing: Dustproof and waterproof with a resistant sealing ring.

Configuration: 4 poles + protective earth (PE).

Screw Male Insert: Offers secure connection options.

4Poles+PE,80A,Screw male insert

Inserts | Suitable Shell:16BHood/Housing |

Number of contacts | 4 |

Electrical data acc. to EN 61 984 |

|

---Rated current | 80A |

---Rated voltage conductor | 830V |

---Rated impulse voltage | 8kV |

---Pollution degree | 3 |

---Pollution degree 2 also | 16A 400/690V 6kV 2 |

Rated voltage acc. to UL/CSA | 600V/300V |

Insulation resistance | ≥1010Ω |

Material | polycarbonate |

Limiting temperatures | -40℃...+125℃ |

Flammability acc. to UL 94 | V0 |

Mechanical working life(mating cycles) | ≥500 |

Contacts |

Material | copper alloy |

Surface | hard-gold plated |

hard-silver plated |

Contact resistance | ≤3mΩ |

terminal |

|

---Wrie gauge | 1.5-16/1.0-2.5mm2 |

---AWG | 16-6/18-14 |

---Tightening/Test torque |

|

---Stripping length |

|

FAQs

1. What is the maximum current capacity of the HK-004/0-M?

2. Is the connector suitable for outdoor use?

3. Can the HK-004/0-M be used with both AC and DC power sources?

4. What materials are used in the construction of the connector?

5. How does the dual locking system work?

6. What environments is the HK-004/0-M suitable for?

The function of the heavy-duty connector

1. Electrical insulation between connectors to avoid interference between signals.

2. Fix the position of the connector, which is conducive to plugging and unplugging and the stability of the position.

3. Provide mechanical protection and support for the insert body.

4. Separate the connector from the application environment, reduce environmental pollution and corrosion of the connector, and extend the service life of the connector.

The advantages of heavy-duty connectors

1. Realize pre-installation, pre-installation of a large number of complicated circuits, which can greatly improve the efficiency of equipment installation and reduce the rate of wiring errors.

2. The heavy-duty connector provides a highly integrated connection, and the abundant combination methods maximize the effective utilization of the equipment space.

3. Heavy-duty connector The connector conveniently and efficiently realizes the modular structure of each functional template block in the equipment, so that the equipment can be transported, installed, maintained and repaired conveniently and safely. Connectors are widely used in the field of power transmission and distribution.

4. The high protection level (IP65, IP68) provided by the heavy-duty connector is incomparable to the advantages of the equipment connection system in the harsh environment. Provide effective protection in harsh environments such as sand, dust, rain, cold, ice and snow, and oil pollution.

Heavy-duty connector wiring method

1. Loosen the screw with a screwdriver, put the wire into the side hole of the insert, and then tighten the screw.

2. To install the upper shell of the heavy-duty connector, use a screwdriver to unscrew the fixing screws of the insert, put the insert into the upper shell, and then tighten the fixing screws.

3. For the installation of the lower shell of the heavy-duty connector, use the same method to fix the lower shell, and insert the upper shell and the lower shell of the inserted body into each other.