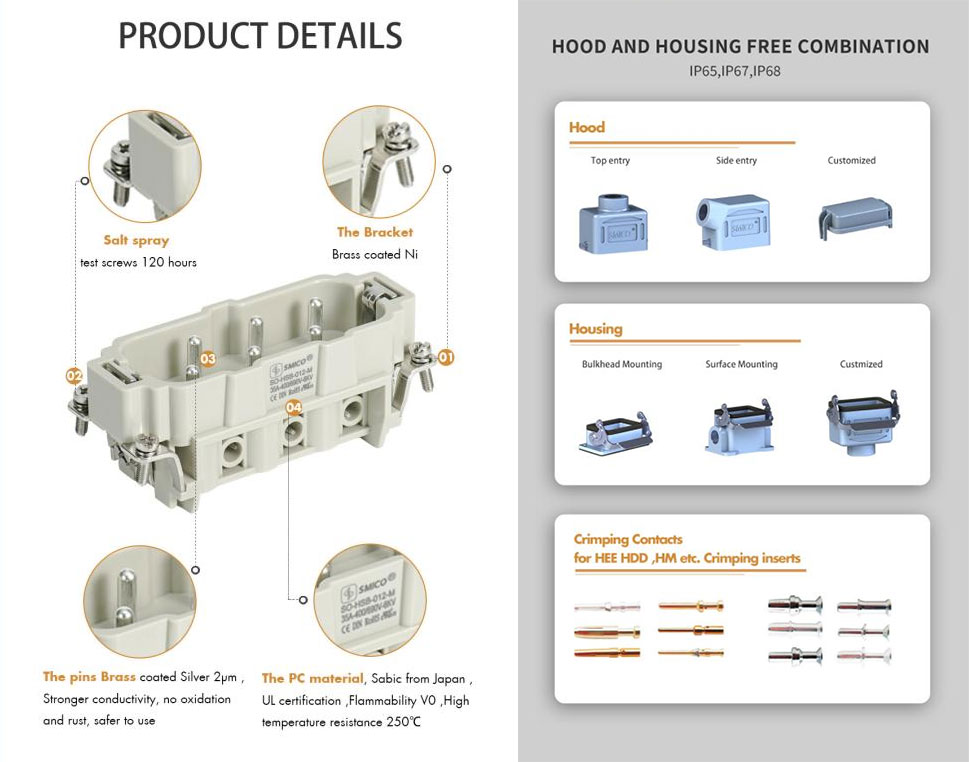

The heavy-duty connector joint cover and casing are widely used in industrial fields, such as power, petroleum, chemical, mechanical manufacturing, railway transportation, etc. They are used to connect various cables and equipment, reliably transmit circuit signals and control signals, and have excellent protective performance to protect equipment from the influence of the external environment.

24 Poles+PE,10A,crimp Female insert

Inserts | Suitable Shell:6BHood/Housing |

Number of contacts | 24 |

Electrical data acc. to EN 61 984 |

|

---Rated current | 10A |

---Rated voltage conductor | 250V |

---Rated impulse voltage | 4kV |

---Pollution degree | 3 |

---Pollution degree 2 also | 10A 230/400V 4kV 2 |

Rated voltage acc. to UL/CSA | 600V |

Insulation resistance | ≥1010Ω |

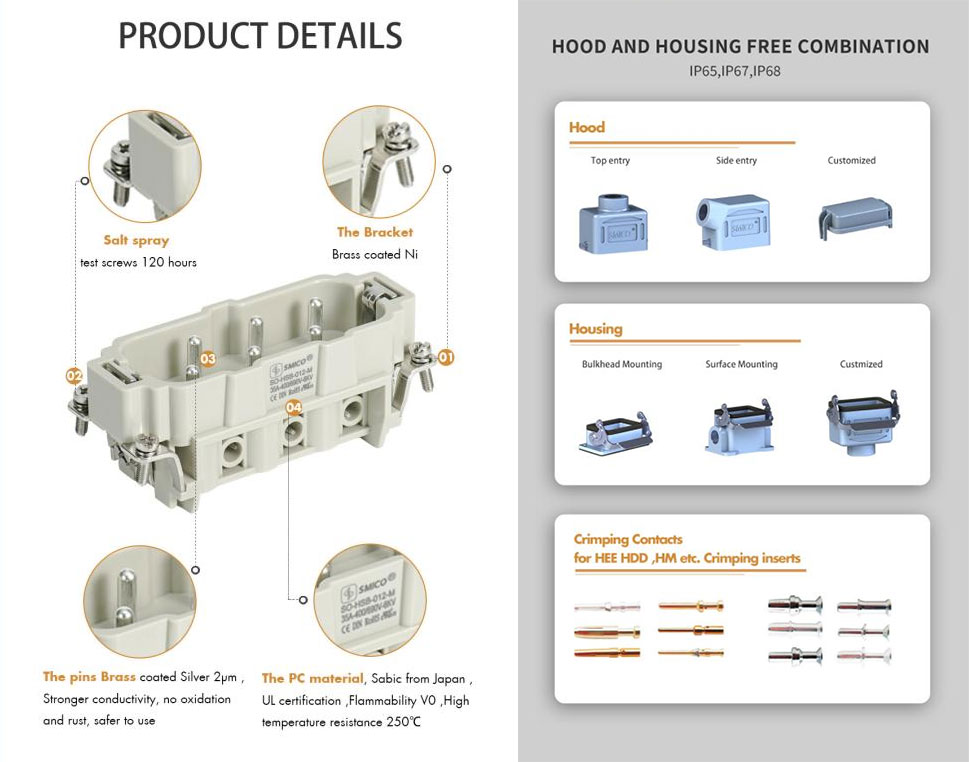

Material | polycarbonate |

Limiting temperatures | -40℃...+125℃ |

Flammability acc. to UL 94 | V0 |

Mechanical working life(mating cycles) | ≥500 |

Contacts |

Material | copper alloy |

Surface | hard-gold plated |

hard-silver plated |

Contact resistance | ≤3mΩ |

Screw terminal |

|

---Wrie gauge | 0.14-2.5mm2 |

---AWG | 26-14 |

---Tightening/Test torque |

|

---Stripping length |

|

The function of the heavy-duty connector

1. Electrical insulation between connectors to avoid interference between signals.

2. Fix the position of the connector, which is conducive to plugging and unplugging and the stability of the position.

3. Provide mechanical protection and support for the insert body.

4. Separate the connector from the application environment, reduce environmental pollution and corrosion of the connector, and extend the service life of the connector.

The advantages of heavy-duty connectors

1. Realize pre-installation, pre-installation of a large number of complicated circuits, which can greatly improve the efficiency of equipment installation and reduce the rate of wiring errors.

2. The heavy-duty connector provides a highly integrated connection, and the abundant combination methods maximize the effective utilization of the equipment space.

3. Heavy-duty connector The connector conveniently and efficiently realizes the modular structure of each functional template block in the equipment, so that the equipment can be transported, installed, maintained and repaired conveniently and safely. Connectors are widely used in the field of power transmission and distribution.

4. The high protection level (IP65, IP68) provided by the heavy-duty connector is incomparable to the advantages of the equipment connection system in the harsh environment. Provide effective protection in harsh environments such as sand, dust, rain, cold, ice and snow, and oil pollution.

Three wiring methods

1. Screw connection

Simple and convenient, with fewer materials, easy to manage

2. Fragment connection

No special tools required, suitable for vibration situations

3. Cold pressing connection

High pin density, strong corrosion resistance, suitable for vibration situations