Description

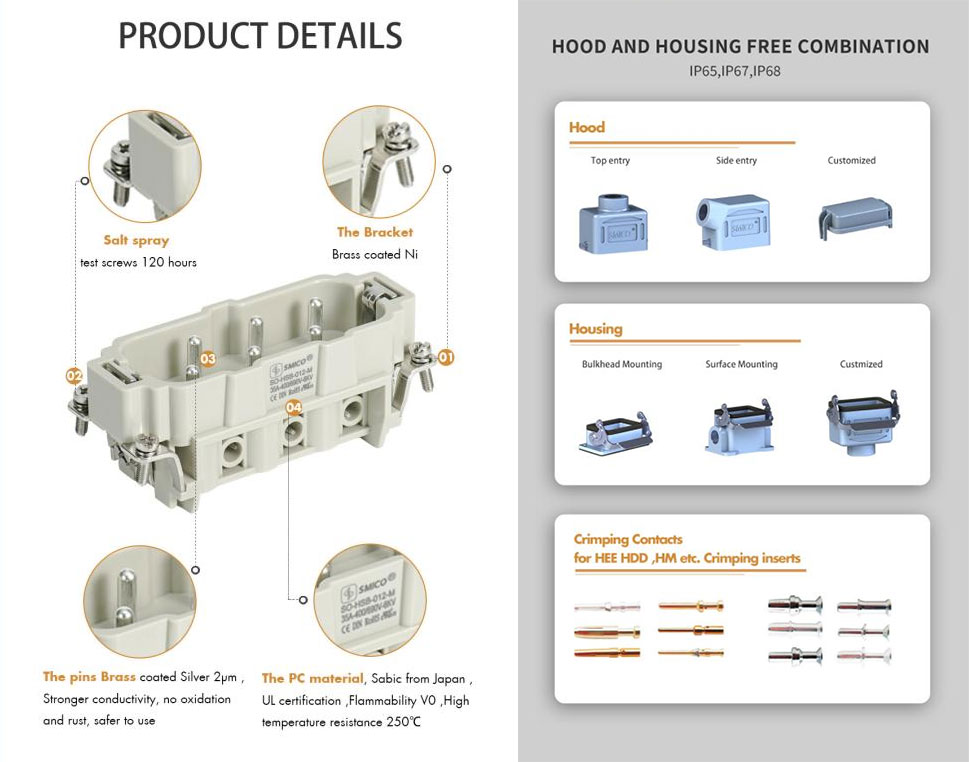

The Conector Dentado features a robust screw termination with wire protection, ideal for various power supplyapplications. Rated for 10A and 250V, this connector includes 64 contacts, making it suitable for a wide range of industrial uses. Its certifications—UL, CUL, CE, ROHS, DMT, and IEC-61984—ensure compliance with international safety standards. Designed for easy installation with a standard screwdriver, it is perfect for heavy-duty environments such as construction and automation.

Key Features

1. Heavy-Duty Design

Engineered for resilience, the Conector Dentado is built to withstand the rigors of industrial applications, providing secure electrical connections in challenging environments.

2. Multiple Applications

This connector is versatile and widely used in machinery across various industries, including construction, textile, packaging, robotics, and rail transit.

3. Easy Installation

With a standard screw termination method, the Conector Dentado allows for quick and easy installation, requiring only a screwdriver for secure connections.

4. High Safety Standards

Certifications from UL, CUL, CE, ROHS, DMT, and IEC-61984 guarantee that the connector meets stringent safety and performance standards, ensuring reliability in operation.

5. Excellent Current and Voltage Ratings

Rated for 10A and 250V, this connector can handle significant electrical loads, making it ideal for demanding power supply applications.

In-Depth Product Description

Reliable Heavy-Duty Performance

The Conector Dentado is designed specifically for high-demand power supply applications. With its heavy-duty construction and robust materials, this connector ensures secure and reliable electrical connections in a variety of industrial settings. It features a screw termination design that provides excellent wire protection, minimizing the risk of disconnection or short circuits.

Versatility Across Industries

With 64 poles and the ability to handle currents of up to 10A, the Conector Dentado is perfect for use in various machinery and equipment. Its applications span construction machinery, textile and packaging machinery, as well as robotics and rail transit systems. The flexibility in application makes it an essential component for any industrial setup requiring reliable electrical connectivity.

Compliance and Safety Standards

Safety is a top priority with the Conector Dentado, which is certified by multiple international standards including UL, CUL, CE, ROHS, DMT, and IEC-61984. These certifications validate the connector's quality and reliability, ensuring that it meets the rigorous demands of modern industrial applications. The ability to operate within these standards offers peace of mind to users, knowing they are employing safe and dependable equipment.

User-Friendly Installation

The design of the Conector Dentado facilitates straightforward installation. Users can easily terminate wires using a standard screwdriver, making it accessible even for those with limited technical experience. This ease of use significantly reduces installation time and increases efficiency on the job site, allowing for quick deployment of electrical systems.

64 Poles+PE,10A,crimp male insert

Inserts | Suitable Shell:24BHood/Housing |

Number of contacts | 64 |

Electrical data acc. to EN 61 984 |

|

---Rated current | 10A |

---Rated voltage conductor | 250V |

---Rated impulse voltage | 4kV |

---Pollution degree | 3 |

---Pollution degree 2 also | 10A 230/400V 4kV 2 |

Rated voltage acc. to UL/CSA | 600V |

Insulation resistance | ≥1010Ω |

Material | polycarbonate |

Limiting temperatures | -40℃...+125℃ |

Flammability acc. to UL 94 | V0 |

Mechanical working life(mating cycles) | ≥500 |

Contacts |

Material | copper alloy |

Surface | hard-gold plated |

hard-silver plated |

Contact resistance | ≤3mΩ |

Screw terminal |

|

---Wrie gauge | 0.14-2.5mm2 |

---AWG | 26-14 |

---Tightening/Test torque |

|

---Stripping length |

|

The function of the heavy-duty connector

1. Electrical insulation between connectors to avoid interference between signals.

2. Fix the position of the connector, which is conducive to plugging and unplugging and the stability of the position.

3. Provide mechanical protection and support for the insert body.

4. Separate the connector from the application environment, reduce environmental pollution and corrosion of the connector, and extend the service life of the connector.

The advantages of heavy-duty connectors

1. Realize pre-installation, pre-installation of a large number of complicated circuits, which can greatly improve the efficiency of equipment installation and reduce the rate of wiring errors.

2. The heavy-duty connector provides a highly integrated connection, and the abundant combination methods maximize the effective utilization of the equipment space.

3. Heavy-duty connector The connector conveniently and efficiently realizes the modular structure of each functional template block in the equipment, so that the equipment can be transported, installed, maintained and repaired conveniently and safely. Connectors are widely used in the field of power transmission and distribution.

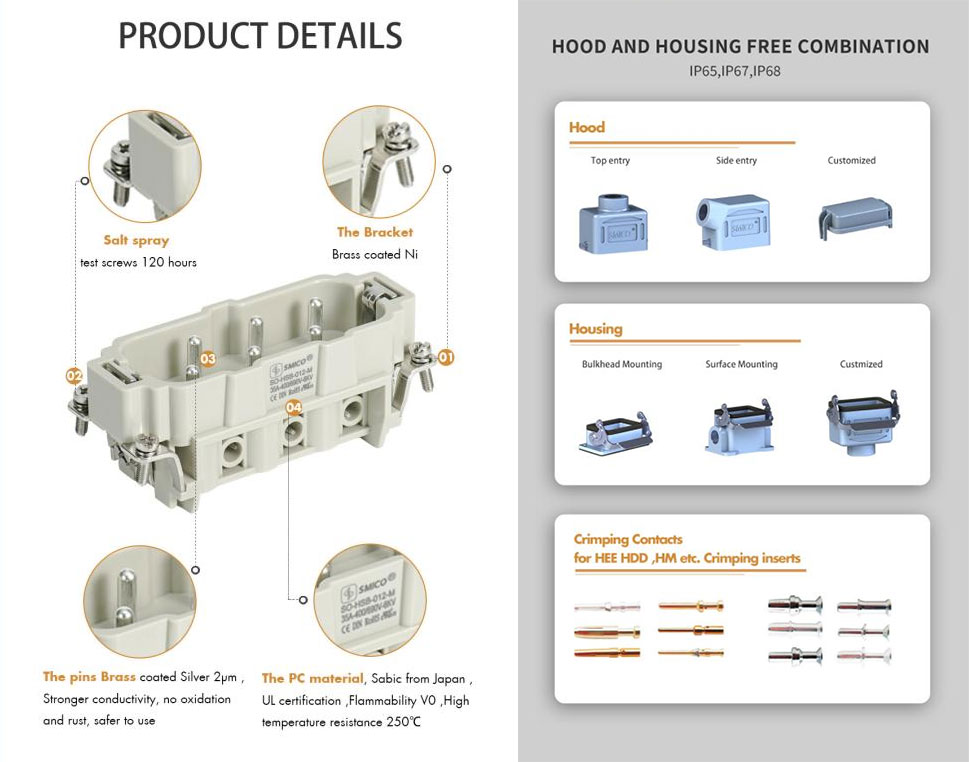

4. The high protection level (IP65, IP68) provided by the heavy-duty connector is incomparable to the advantages of the equipment connection system in the harsh environment. Provide effective protection in harsh environments such as sand, dust, rain, cold, ice and snow, and oil pollution.

Heavy-duty connector wiring method

1. Loosen the screw with a screwdriver, put the wire into the side hole of the insert, and then tighten the screw.

2. To install the upper shell of the heavy-duty connector, use a screwdriver to unscrew the fixing screws of the insert, put the insert into the upper shell, and then tighten the fixing screws.

3. For the installation of the lower shell of the heavy-duty connector, use the same method to fix the lower shell, and insert the upper shell and the lower shell of the inserted body into each other.

How to Use

Preparation: Ensure that the power supply is turned off before beginning installation. Gather the necessary tools, including a standard screwdriver and wire strippers.

Wire Preparation: Strip approximately 1/2 inch of insulation from the end of each wire you intend to connect. Make sure the strands are untangled and neatly aligned.

Insertion: Insert the stripped end of the wire into the designated terminal on the Conector Dentado. Ensure that the wire is fully inserted and making contact with the metal parts.

Screw Tightening: Using a standard screwdriver, tighten the screw until it securely grips the wire. The connector is designed to shear off at the appropriate torque, ensuring a perfect fit without over-tightening.

Final Check: Once all connections are made, visually inspect to ensure that each wire is securely fastened. Turn the power supply back on and test the connections to ensure proper functionality.

FAQs

1. What are the current and voltage ratings for the Conector Dentado?

It is rated for 10A and 250V.

2. How many contacts does the connector have?

The Conector Dentado features 64 contacts.

3. Is it easy to install?

Yes, it uses a standard screw termination method, making installation straightforward with a screwdriver.

4. In which industries can this connector be used?

It is widely used in construction, textile, packaging, robotics, and rail transit industries.

5. What certifications does the Conector Dentado have?

It is certified by UL, CUL, CE, ROHS, DMT, and IEC-61984.

6. What materials are used in the construction?

The connector is made from durable materials, ensuring reliability in harsh environments.