Description

The H2M-SK-M25 Heavy Duty Waterproof Connector is designed to provide reliable electrical connections in demanding environments. Featuring an IP65-rated aluminum die-cast housing, it protects against dust and water, making it ideal for industrial and outdoor use. The connector’s side-entry design allows for easy installation in tight spaces, while its robust locking system ensures secure connections. Certified by UL, CE, ROHS, and IEC-61984, the H2M-SK-M25 meets the highest industry standards for safety and performance. Suitable for a wide range of applications, including construction, automation, and rail systems.

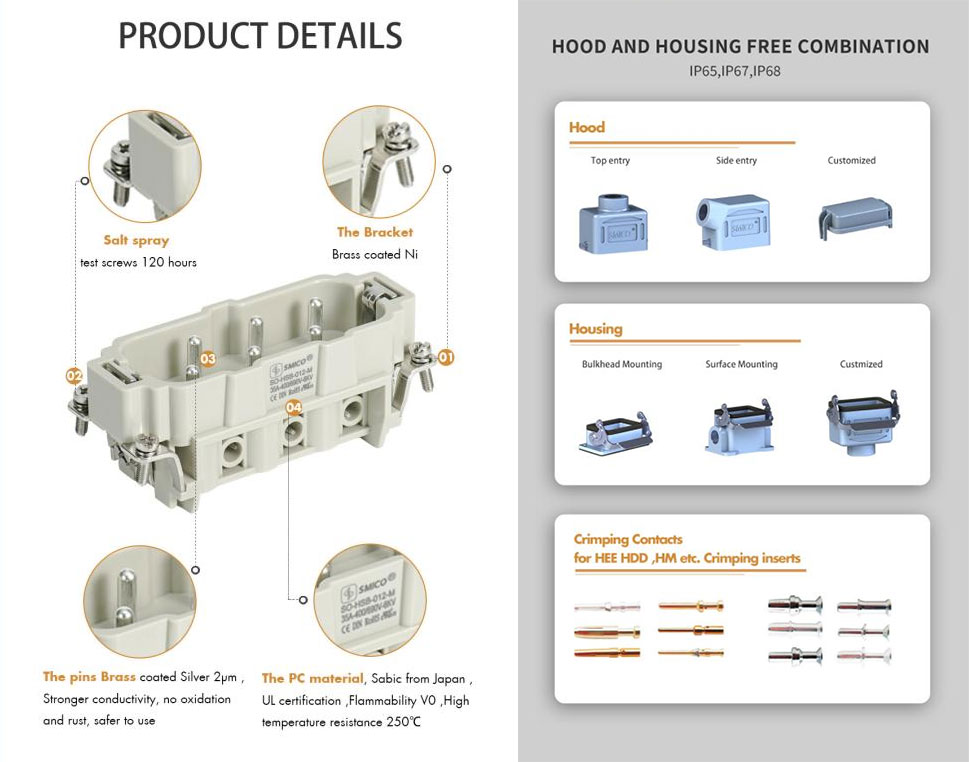

Product Features

IP65 Protection: Fully sealed to prevent dust and water ingress, ensuring durability in harsh environments.

Side Entry Design: Allows for easy cable entry and installation, especially in space-constrained areas.

Robust Construction: Made of aluminum die-cast for long-lasting performance in industrial applications.

Certified Safety: UL, CE, ROHS, and IEC-61984 certifications guarantee quality and compliance with international standards.

Strong Locking Mechanism: Four locking points ensure secure and stable connections even under high vibration.

Easy Installation: Screw and bayonet locking systems allow for simple and fast assembly using standard tools.

Product Description

Introduction to the H2M-SK-M25 Heavy Duty Waterproof Connector

The H2M-SK-M25 is a premium heavy-duty connector engineered to deliver dependable electrical connections in challenging industrial environments. With an IP65-rated aluminum die-cast housing, this connector offers superior protection against dust and water, making it ideal for outdoor installations and harsh conditions. Its innovative side-entry design enables easy cable installation, even in confined spaces where traditional connectors may not fit.

This connector is widely used across various industries, including construction machinery, automation, and rail transit, due to its durability and reliability. It is perfect for power and signal transmission in applications where consistent performance is essential.

Reliable Locking and High-Performance Design

One of the key features of the H2M-SK-M25 is its robust locking mechanism. Equipped with four locking points, the connector ensures secure connections, even in high-vibration environments such as those found in heavy machinery or rail systems. The two-lever system on both the hood and housing allows for quick and easy installation while maintaining a strong hold.

The screw and bayonet locking system offers additional protection against accidental disconnections. Whether you’re installing the connector in an industrial setting or on construction machinery, you can rely on its vibration-proof design and secure locking to maintain stable connections.

Safety and Compliance

The H2M-SK-M25 is not only built for performance but also for safety. Certified by UL, CE, ROHS, and IEC-61984, this connector meets rigorous safety and environmental standards. This ensures that it’s suitable for a wide range of industrial applications, providing users with peace of mind that their equipment is compliant with international regulations.

Applications

The H2M-SK-M25 is ideal for use in a variety of industries, including construction, packaging, rail transit, and automation. Its robust design and reliable performance make it an excellent choice for applications that require frequent electrical and signal connections in harsh or outdoor environments.

How to Maintain

Regular Inspection: Periodically check the connector’s housing and locking mechanisms for signs of wear or damage, especially in high-vibration or outdoor settings.

Clean the Housing: Wipe down the aluminum die-cast housing with a dry or slightly damp cloth to remove dust or debris. Avoid using harsh chemicals.

Tighten Locking Points: Ensure the locking levers are securely fastened after each use, especially in environments where vibration is common.

Check IP65 Sealing: Verify the sealing of the housing to ensure the connector remains fully protected against dust and moisture.

Replace Damaged Components: If any part of the connector shows wear, such as loose screws or damaged levers, replace the components immediately to maintain optimal performance.

FAQs

Q: What is the IP rating of the H2M-SK-M25 connector?

A: The connector has an IP65 rating, which ensures protection against dust and water, making it suitable for harsh environments.

Q: Can this connector handle high-vibration conditions?

A: Yes, the H2M-SK-M25 is designed to withstand high-vibration environments, making it ideal for industrial machinery and rail systems.

Q: What tools are needed for installation?

A: Installation is simple and requires only standard tools like a screwdriver or hexagon wrench.

Q: Is this connector certified for safety and environmental standards?

A: Yes, the H2M-SK-M25 is certified by UL, CE, ROHS, and IEC-61984, meeting the highest international safety and quality standards.

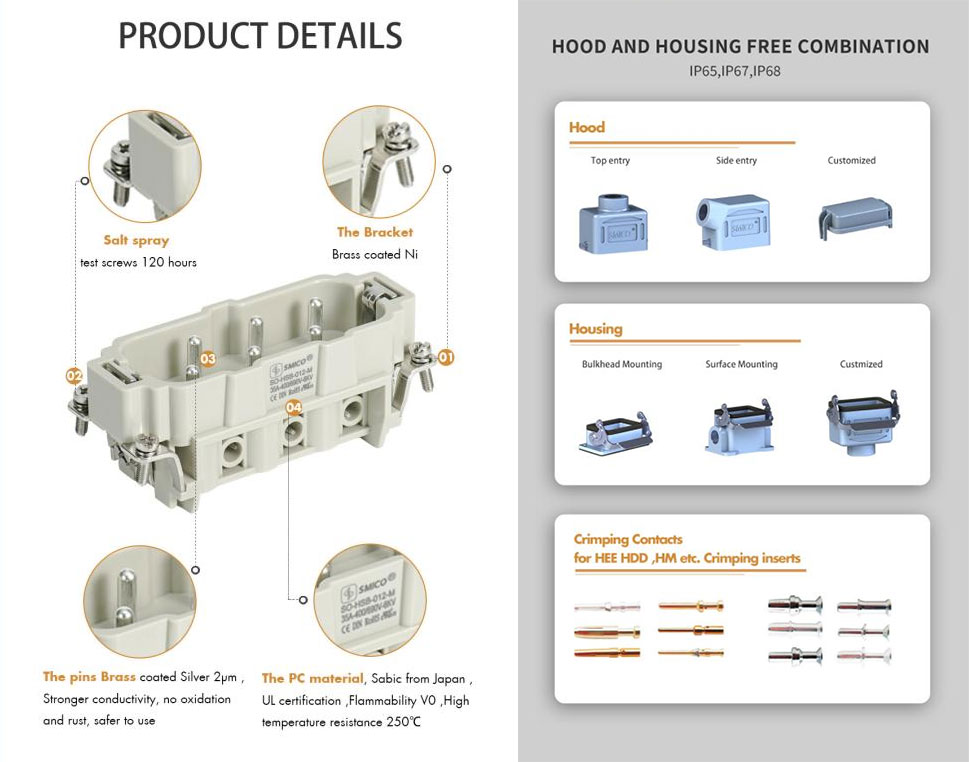

Two levers at the bottom part of the housing

o Secure locking ensured by four locking points

o Minimal space requirements and high locking force

o Ideal for laterally arranged connectors

Two levers on the hood

o Secure locking ensured by four locking points

o Minimal space requirements and high locking forces

o Ideal for laterally arranged connectors and surface-mounted housings with caps

One lever at the bottom part of the housing

o Two locking points along the longitudinal axis

o Easy to access even with cable entering laterally

o Cap on the upper part of the housing can be locked

Screw / bayonet locking system

o Actuated using a hexagon wrench or screwdriver

o Vibration-proof connections with outstanding sealing effect

o Easy to access even with cable entering laterally

o Prevents accidental or unauthorized opening

Hood Link locking system

o A resistant elastomer element connects and seals (IP65) hood and housing

o Ideal for quick and easy (flying) cable-to-cable connections

o Resistant to oils and gases; absorbing external mechanical forces

| Material | aluminium die-cast |

| Colour | Grey |

| Locking element |

|

| ---Lever type | metal elastic pressing |

| ---Material | Stainless steel |

| Hoods/Housing sealing | NBR |

| Limiting temperatures | -40℃...+125℃ |

| Flammability acc.to UL 94 | V0 |

| Degree of protection acc.to EN 60529 for coupled connector | IP65 |

The function of the heavy-duty connector

1. Electrical insulation between connectors to avoid interference between signals.

2. Fix the position of the connector, which is conducive to plugging and unplugging and the stability of the position.

3. Provide mechanical protection and support for the insert body.

4. Separate the connector from the application environment, reduce environmental pollution and corrosion of the connector, and extend the service life of the connector.

The advantages of heavy-duty connectors

1. Realize pre-installation, pre-installation of a large number of complicated circuits, which can greatly improve the efficiency of equipment installation and reduce the rate of wiring errors.

2. The heavy-duty connector provides a highly integrated connection, and the abundant combination methods maximize the effective utilization of the equipment space.

3. Heavy-duty connector The connector conveniently and efficiently realizes the modular structure of each functional template block in the equipment, so that the equipment can be transported, installed, maintained and repaired conveniently and safely. Connectors are widely used in the field of power transmission and distribution.

4. The high protection level (IP65, IP68) provided by the heavy-duty connector is incomparable to the advantages of the equipment connection system in the harsh environment. Provide effective protection in harsh environments such as sand, dust, rain, cold, ice and snow, and oil pollution.

Heavy-duty connector wiring method

1. Loosen the screw with a screwdriver, put the wire into the side hole of the insert, and then tighten the screw.

2. To install the upper shell of the heavy-duty connector, use a screwdriver to unscrew the fixing screws of the insert, put the insert into the upper shell, and then tighten the fixing screws.

3. For the installation of the lower shell of the heavy-duty connector, use the same method to fix the lower shell, and insert the upper shell and the lower shell of the inserted body into each other.