Product Overview

The H16BS-G-2L-M25 Heavy Power Connector is engineered for high-performance applications, featuring a durable aluminium die-cast construction and an IP65 rating for water and dust protection. This connector is perfect for various industries, including construction, textile machinery, and automation. With secure locking mechanisms and easy installation using standard tools, it meets international certifications (UL, CE, ROHS) and is designed for reliable operation in harsh environments.

Key Features

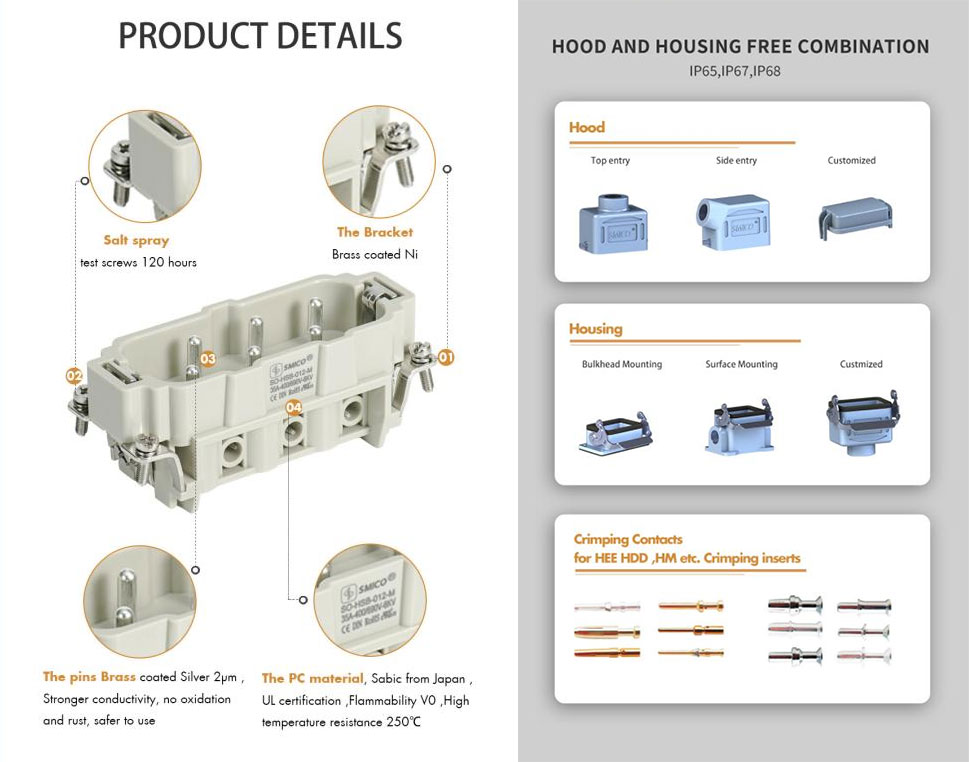

1. Durable Construction

Made from high-quality aluminium die-cast material, the H16BS-G-2L-M25 connector is built to withstand the rigors of heavy-duty applications, ensuring long-lasting performance.

2. IP65 Rating

This connector offers excellent protection against dust and moisture, making it suitable for outdoor and industrial environments.

3. Secure Locking Mechanisms

Featuring multiple locking points and a vibration-proof screw/bayonet locking system, the connector ensures secure and reliable connections, preventing accidental disconnections.

4. Easy Installation

Designed for quick assembly, it requires only standard tools for termination, streamlining the installation process for users.

5. Versatile Applications

Ideal for various industries, including rail transit, robotics, and automation, the connector provides a reliable solution for electrical and signal connections.

In-Depth Product Description

High-Performance Design

The H16BS-G-2L-M25 Heavy Power Connector stands out for its robust design, specifically intended for power supply applications. The connector's aluminum die-cast body not only provides exceptional durability but also facilitates heat dissipation, which is crucial for maintaining performance in high-load scenarios. With a rated voltage of 250V and a current capacity of 10A, it is perfect for heavy-duty usage in various industrial settings.

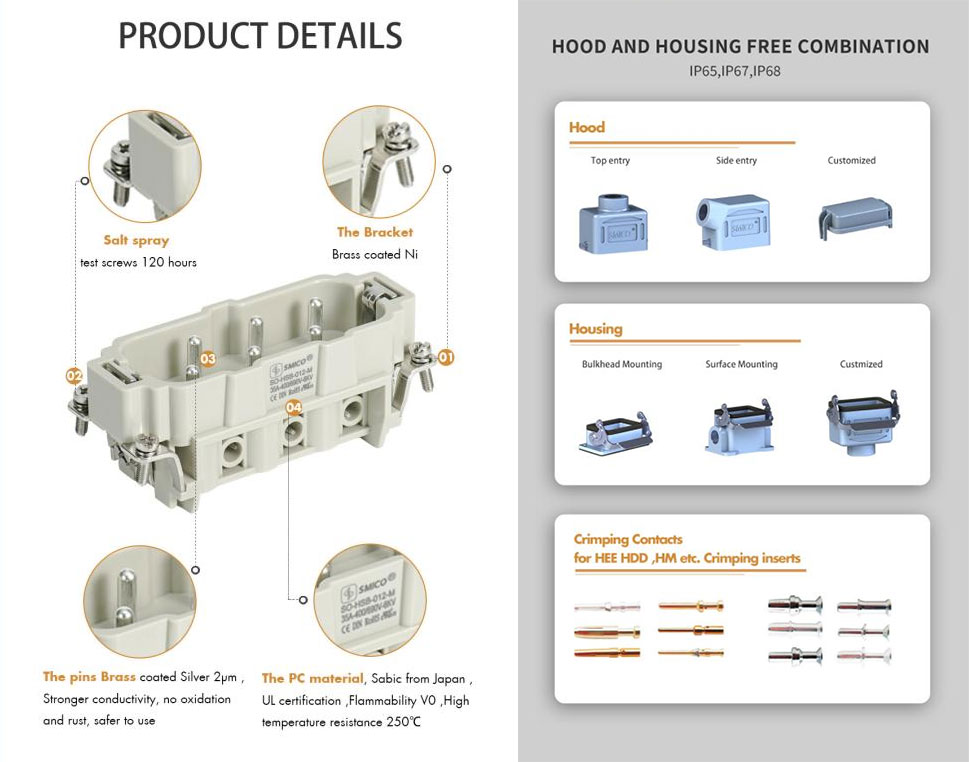

Effective Sealing and Locking

With an IP65 rating, this connector is resistant to both dust and moisture, ensuring reliable performance even in challenging environments. Its locking system includes multiple levers that secure the connection firmly, utilizing four locking points to minimize space requirements while maximizing locking force. The screw and bayonet locking mechanism is easy to operate with a standard hexagon wrench or screwdriver, providing vibration-proof connections that withstand external mechanical forces.

Simplified Installation Process

Designed with user convenience in mind, the H16BS-G-2L-M25 connector allows for quick installation without specialized tools. The straightforward screw termination method ensures that users can achieve secure connections efficiently. Furthermore, the elastomer sealing element in the hood-link locking system provides a quick and easy way to make cable-to-cable connections, enhancing its versatility across different applications.

How to Use

Preparation: Ensure all components are clean and dry before beginning the installation process.

Insert Cable: Use a standard screwdriver to loosen the screw termination. Insert the prepared cable into the connector housing.

Secure Connection: Tighten the screws to secure the cable in place, ensuring a snug fit to prevent accidental disconnection.

Locking Mechanism: Engage the locking levers to secure the connector. Ensure all points are firmly locked.

Test the Connection: After installation, conduct a functionality test to ensure the connection operates as expected.

Two levers at the bottom part of the housing

o Secure locking ensured by four locking points

o Minimal space requirements and high locking force

o Ideal for laterally arranged connectors

Two levers on the hood

o Secure locking ensured by four locking points

o Minimal space requirements and high locking forces

o Ideal for laterally arranged connectors and surface-mounted housings with caps

One lever at the bottom part of the housing

o Two locking points along the longitudinal axis

o Easy to access even with cable entering laterally

o Cap on the upper part of the housing can be locked

Screw / bayonet locking system

o Actuated using a hexagon wrench or screwdriver

o Vibration-proof connections with outstanding sealing effect

o Easy to access even with cable entering laterally

o Prevents accidental or unauthorized opening

Hood Link locking system

o A resistant elastomer element connects and seals (IP65) hood and housing

o Ideal for quick and easy (flying) cable-to-cable connections

o Resistant to oils and gases; absorbing external mechanical forces

| Material | aluminium die-cast |

| Colour | Grey |

| Locking element |

|

| ---Lever type | metal elastic pressing |

| ---Material | Stainless steel |

| Hoods/Housing sealing | NBR |

| Limiting temperatures | -40℃...+125℃ |

| Flammability acc.to UL 94 | V0 |

| Degree of protection acc.to EN 60529 for coupled connector | IP65 |

The function of the heavy-duty connector

1. Electrical insulation between connectors to avoid interference between signals.

2. Fix the position of the connector, which is conducive to plugging and unplugging and the stability of the position.

3. Provide mechanical protection and support for the insert body.

4. Separate the connector from the application environment, reduce environmental pollution and corrosion of the connector, and extend the service life of the connector.

The advantages of heavy-duty connectors

1. Realize pre-installation, pre-installation of a large number of complicated circuits, which can greatly improve the efficiency of equipment installation and reduce the rate of wiring errors.

2. The heavy-duty connector provides a highly integrated connection, and the abundant combination methods maximize the effective utilization of the equipment space.

3. Heavy-duty connector The connector conveniently and efficiently realizes the modular structure of each functional template block in the equipment, so that the equipment can be transported, installed, maintained and repaired conveniently and safely. Connectors are widely used in the field of power transmission and distribution.

4. The high protection level (IP65, IP68) provided by the heavy-duty connector is incomparable to the advantages of the equipment connection system in the harsh environment. Provide effective protection in harsh environments such as sand, dust, rain, cold, ice and snow, and oil pollution.

Heavy-duty connector wiring method

1. Loosen the screw with a screwdriver, put the wire into the side hole of the insert, and then tighten the screw.

2. To install the upper shell of the heavy-duty connector, use a screwdriver to unscrew the fixing screws of the insert, put the insert into the upper shell, and then tighten the fixing screws.

3. For the installation of the lower shell of the heavy-duty connector, use the same method to fix the lower shell, and insert the upper shell and the lower shell of the inserted body into each other.

FAQs

1. What is the IP rating of the H16BS-G-2L-M25 connector?

The connector has an IP65 rating, providing excellent protection against dust and moisture.

2. What materials are used in this connector?

The body is made from aluminium die-cast, ensuring durability, while the internal components include high-quality engineering plastics.

3. Can this connector be used outdoors?

Yes, the IP65 rating makes it suitable for outdoor applications where moisture and dust may be present.

4. What tools are needed for installation?

Standard tools such as a screwdriver or hexagon wrench are sufficient for installation.

5. What industries commonly use this connector?

It is widely used in construction, textile machinery, robotics, rail transit, and automation systems.

At Papa Food Machine Company, we are dedicated to providing state-of-the-art connectors that optimize electrical and signal connections, ensuring your operations run smoothly and efficiently. Our commitment to quality and innovation empowers our clients to achieve excellence in their industries. Choose the H16BS-G-2L-M25 Heavy Power Connector for reliable, high-performance solutions.

Heavy-duty connectors, also known as HDC heavy-duty connectors, aviation plugs, are widely used in construction machinery, textile machinery, packaging and printing machinery, tobacco machinery, robots, rail transit, hot runners, electricity, automation, etc. that require electrical and signal connections In the device.