Description

The SMICO Composite Pin Insulator, model FPQ, is designed to deliver outstanding electrical insulation and mechanical durability. It features excellent water-repellent properties, making it ideal for wet environments. Resistant to aging, electrical tracking, and surface erosion, this polymeric pin-type insulator is lightweight, facilitating easier installation compared to traditional porcelain insulators. Engineered with a silicone housing, core rod, and end fittings, it offers superior strength and pollution resistance. Additionally, the insulator is interchangeable with porcelain insulators, providing seamless installation in existing setups. Available in various colors, the FPQ insulator complies with GB/T 19519-2014 and IEC 61109 standards.

Product Features

Hydrophobicity: Excellent water-repellent properties, performing well in wet environments.

Anti-Aging: Highly durable and resistant to aging, extending the lifespan.

Tracking and Erosion Resistance: Prevents electrical tracking and surface erosion for long-term reliability.

High Mechanical Strength: Offers high tensile strength, bending strength, and shock resistance.

Lightweight & Easy Installation: Light in weight, easy to transport and install.

Interchangeable with Porcelain Insulators: Compatible with standard porcelain pin-type insulators.

Pollution Resistance: Effective in highly polluted environments.

Standards Compliance: Meets GB/T 19519-2014 and IEC 61109 standards.

Color Options: Red, gray, blue, yellow, or custom colors available.

Product Description

Introduction to SMICO Composite Pin Insulator

The SMICO Composite Pin Insulator (Model FPQ) is a top-tier solution for overhead power line insulation, designed to provide excellent performance in various environmental conditions. Constructed with advanced materials such as silicone housing, core rod, and high-quality end fittings, this insulator is engineered to withstand harsh weather, pollution, and electrical stress. Whether installed in urban or rural settings, the insulator maintains strong and reliable performance, meeting the stringent standards of GB/T 19519-2014 and IEC 61109.

Durable and Reliable Design

One of the standout features of the SMICO Composite Pin Insulator is its hydrophobicity. The silicone material repels water effectively, preventing moisture accumulation, which can reduce the risk of leakage currents or flashovers during heavy rain or dew formation. This unique property makes it ideal for use in wet or high-humidity environments.

The insulator is also built to be anti-aging. With its durable composition, it resists the effects of aging caused by UV radiation, ozone, and other environmental factors. This ensures long-term reliability, reducing maintenance and replacement costs over the years. Additionally, the insulator has tracking and erosion resistance, which protects the surface from damage and ensures the integrity of the insulator even in polluted or industrial settings.

Superior Mechanical Strength & Easy Installation

The SMICO Composite Pin Insulator is known for its high mechanical strength, boasting strong tensile and bending resistance. It can endure extreme mechanical stress, wind forces, and impact, making it ideal for overhead lines in regions prone to harsh weather conditions.

Weighing significantly less than traditional porcelain insulators, the lightweight nature of this composite insulator simplifies the transportation and installation process. Its dimensions are fully compatible with standard porcelain pin-type insulators, allowing for interchangeability without the need for structural adjustments in existing systems.

Versatility in Applications

HV transmission lines,suitable for polluted areas

Variety scope: 10kV(11kV)

Specified mechanical load: 3kN,

Color: Red,Gray,Blue,Yellow or according to customer’s requirement.

Executive Standard:GB/T 19519-2014 IEC 61109

How to Use

Preparation: Ensure all electrical equipment is powered off and proper safety precautions are in place before installation.

Installation: The lightweight design makes the insulator easy to handle. Align the pin insulator with the existing structure, ensuring compatibility with existing systems. The interchangeable dimensions allow for seamless replacement of porcelain insulators.

Inspection: Regularly inspect the insulator for any signs of wear, particularly in highly polluted environments, to ensure optimal performance.

Maintenance: Little maintenance is required due to the hydrophobicity and pollution resistance of the material. Clean as needed to prevent excessive dirt or dust buildup.

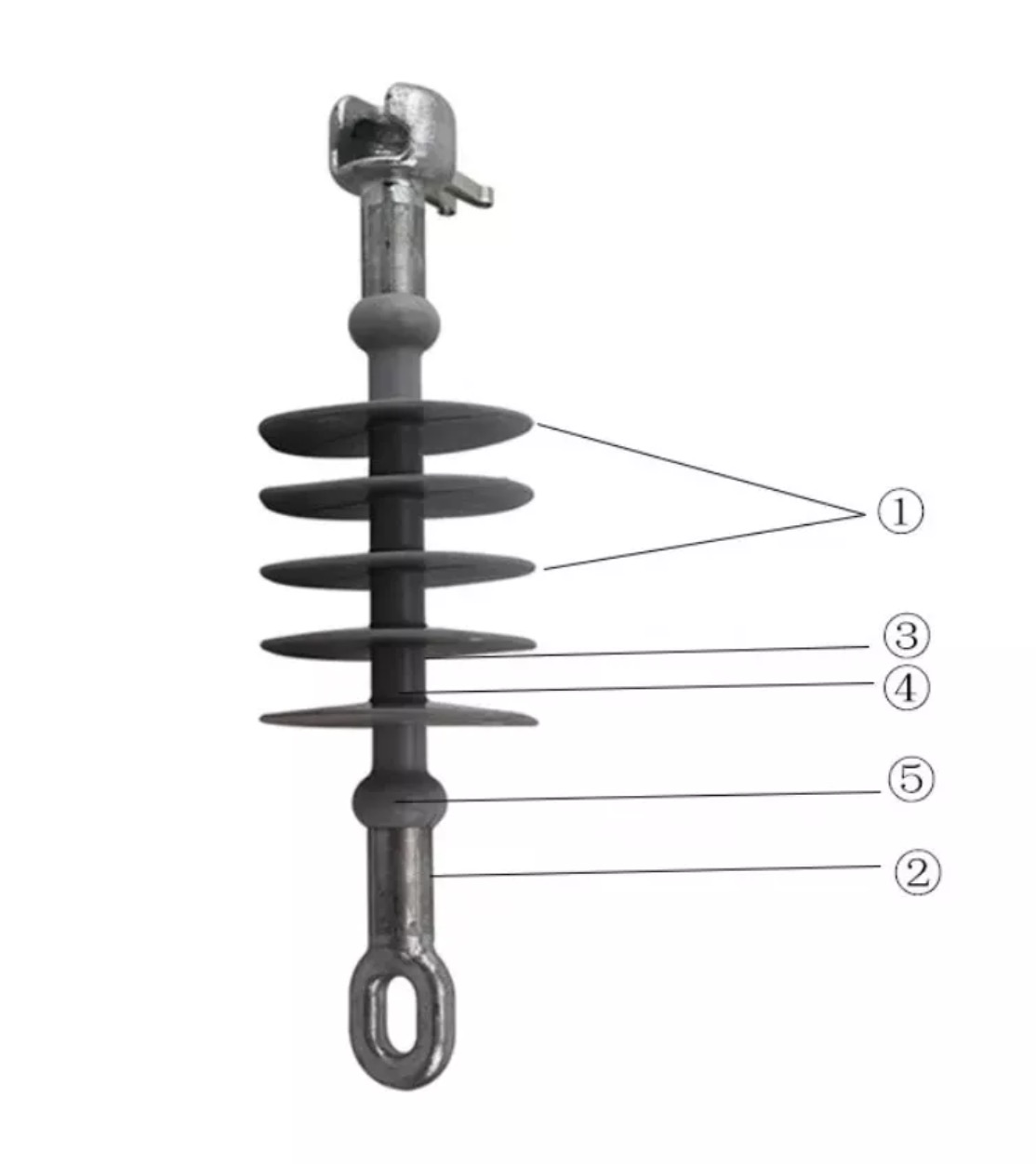

Structure

Be made of silicone housing, core rod and end fitting.

Manufacturing Process

Complete injection technology advantage:Core rod and sheath adhesive without aperture, the inner insulation performance is good, can avoid interface breakdown phenomenon.

FAQs

Q: What standards does the Composite Pin Insulator comply with?

A: The insulator conforms to GB/T 19519-2014 and IEC 61109 standards.

Q: Can the insulator be used in polluted environments?

A: Yes, the insulator is highly resistant to pollution, making it ideal for industrial or coastal regions.

Q: Is the insulator compatible with porcelain insulators?

A: Yes, the installation dimensions are the same, allowing for easy interchangeability with porcelain insulators.

Q: What are the available color options?

A: The Composite Pin Insulator is available in red, gray, blue, yellow, or custom colors.

Q: What is the expected lifespan of this insulator?

A: The insulator is designed with anti-aging properties, offering a long service life even in harsh environmental conditions.